- Home

- Germany Jaeger High-speed Electric Spindle High-performance

- FDG-700 Double End Grinding Machine iMCS Connects Wisdom

- CHEVALIER SMART-B818III CNC Forming Grinder

- Taiwan CHevalIER FVGC Vertical Grinding Center Machine Easy to operate, flexible

- CHEVALIER three-axis automatic control high-precision surface grinder FSG-2440AD

- Taiwan CHevalIER Uni5X400,600,800 series, five-axis machining center machine

- FVGC-40,50,60,63,U60 TC-V4 New Energy Industry

- CHEVALIER three-axis automatic control high-precision surface grinder FSG-2040AD

- Taiwan CHevalIER fixed beam heavy-duty gantry grinder, FSG-40120DC, FSG-50120DC

- SMART-B1640III iMCS connects wisdom

- FVGC-50_Semiconductor Industry iMCS Connect Wisdom Quartz ring processing

- FVGC-50_Screw Industry, iMCS Connect Wisdom, Punch Bar Processing Application

- Taiwan CHevalIER Fully Automatic Control Surface Grinding Machine FSG-1224ADIII

- Fully automatic control surface grinder FSG-1632ADIII

- CHEVALIER SMART-B818III high-intelligence CNC forming grinder on the ultrasonic

- Taiwan CHEVALIER-FLG-4M Linear Guide Grinding Machine-SMART-B600

- UNi5X-800 iMCS connects wisdom crane type five-axis machining center

- Taiwan CHevalIER Heavy Cutting CNC Slow Feed Forming Grinding Machine FSG-C1224C

- Cylindrical Grinder FCG-P2040CNC/2060CNC/FCG-A2040CNC

- FGC5X-600 iMCS Connecting Wisdom Five-axis Vertical Grinding Center

- FSG-2A818,FSG-3A818 automatic surface grinder, Taiwan Chevalier

- FVL-1600VTC CY iMCS Connecting Wisdom High-precision large-scale composite

- FMG-1632 CNC three-axis moving column mass production type iMCS connected with w

- Large truck tire production line iMCS connects wisdom

- Lithium battery coating nozzle FSG-12_16_20

- Taiwan CHevalIER High Efficiency CNC Forming Grinding Machine FSG-B818CNC FSG-H8

- FMG-B1224 High-efficiency moving column type iMCS connects wisdom CNC precision

- CHEVALIER 4 plus 1CNC Milling Uni5X-400

- FVL-12MC Vertical Lathe Series iMCS Connects Wisdom

- Taiwan CHEVALIER three-axis automatic control high-precision surface grinder FSG

- UNi5X-400_Automotive Industry iMCS Connects Wisdom Aluminum rim processing

- SMART-1640III iMCS connects wisdom, multifunctional CNC surface grinder

- CHevalIER FSG-1632-2048-2064ADIV Mirror display, lithium battery nozzle and cutt

- Gantry Grinder KMG-1620/1630/2130DC

- FVM-133200DC iMCS connects wisdom, new generation heavy-duty gantry milling mach

- Surface Grinder FSG-2/3A1224

- Taiwan FSG-DC series CNC grinder, gantry grinder

- TaiwanNC moving column automatic surface grinder FSG-2048_2064ADIV

- Taiwan Chevalier Multifunctional CNC Lathe Grinding Machine Five-axis Machining

- FSG-ADIV Series iMCS Connect Wisdom CNC Surface Grinding Machine

- MT-LINKi-CT-FANUC system

- Support FANUC-iMCS product description Siemens controller

- iMCS piston production line simulation briefing NC program download

- SMART-III series iMCS connects wisdom, high-intelligence CNC forming grinder

- Taiwan CHevalIER three-axis automatic control high-precision surface grinder FSG

- FSG-DC series iMCS connects wisdom fixed beam gantry grinder

- CHEVALIER FSG-ADIV Smart Grinding Machine

- SkyMars-FANUC-Mitsubishi-Heidenhain-New Generation-Baoyuan-Siemens Controller

- iMCS product description Siemens controller

- iMCS connects smart manufacturing

- Sodick spark machine Sodick discharge machine Sodick WEDM-Sodick Wire Cutting

- Sodick slow wire cutting ALN400G

- Sodick WEDM-Sodick Wire Cutting ALN400G_600G

- Sodick spark machine Sodick discharge machine AL40Gs-AL60Gs

- Sodick Wire Cutting AL400G

- Mirror spark machine (Sodick) AG40L specification

- Sodick WEDM-Sodick Wire Cutting ALN400Qs-ALN600Qs

- FOCUS CNC Turning and Milling Machine FNL-220Y,LY,LSY,LS,LSMC FBL-250Y, 320Y, SY

- FOCUS Technology CNC Large Lathe Series FBL-510,520,530,540MC

- FOCUS CNC FBL-360,460L-MC

- FOCUS CNC FBL-300L-MC

- FOCUS CNC FBL-230MC-200L

- FOCUS CNC FCL-300P-MC

- FOCUS CNC FCL-200HT-MC

- FOCUS CNC FCL-140A

- FOCUS CNC FCL-130A-R

- FOCUS CNC technology line rail, hard rail, CNC turning and milling machine , CNC

- Fushuo FBL-250SY Horizontal Turning and Milling Compound Lathe

- Taiwan CNC large lathe FBL-520, 530, 540MC series

- FOCUS CNC Professional Aluminum Alloy Wheel Processing Machine FBL-300 W17,20

- HASEGAWA TZ25 high-precision composite 4-axis rotary milling machine

- Korea EZ-345CNC punching machine

- Italy COORD3 KRONOS series coordinate measuring machine

- Japan Union-GaAs infrared CCD observation wafer-DZ2-IR

- PV-12 vertical erect projector OpTecMaster from Japan

- Japan Union-With surface and transmission light source Observation chip-Microsco

- Japan KIRA Kira three-axis robot system multi-joint robot

- Japan KIRA Kira new machine-PCV-30S three-axis robot system

- Japan Union-Infrared observation and measurement microscope-DZ2-IR

- Japan AMADA Turning and Milling Machine

- Japan AMADA Optical Curve Grinder

- NAKANISHI online training

- NAKANISHI-sonic-cutter-zero

- NAKANISHI-NR33-6000ATC-ESD

- NAKANISHI-hes

- NAKANISH-Icts-3030

- NAKANISHI-e2000-e3000

- NAKANISH-airspeed

- Rs ultrasonic spindle can alternate with traditional tools through ATC

- Japan Union-dh2_Microscope-Manufacturing method of indentation die-Thickness

- Electrical discharge machine,spark machine ST-230 ST-345 ST-450 ST-560

- Electric discharge machining electric control box

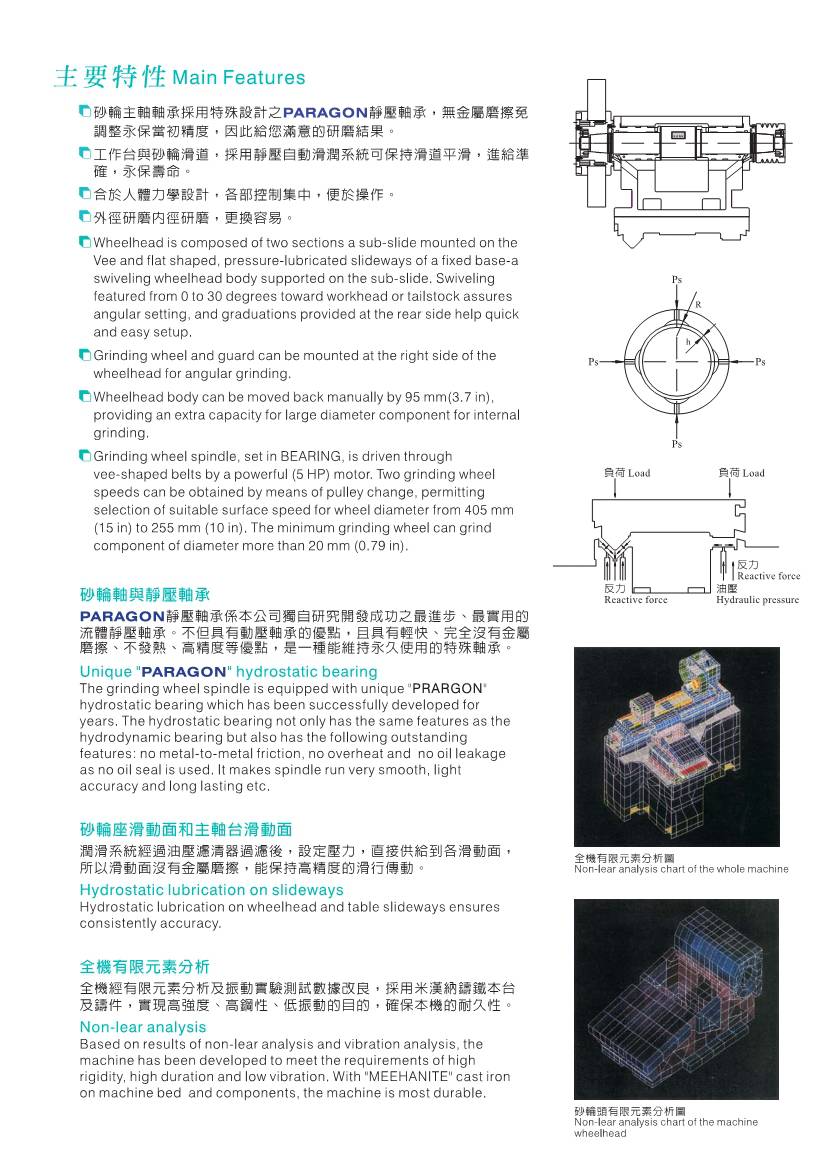

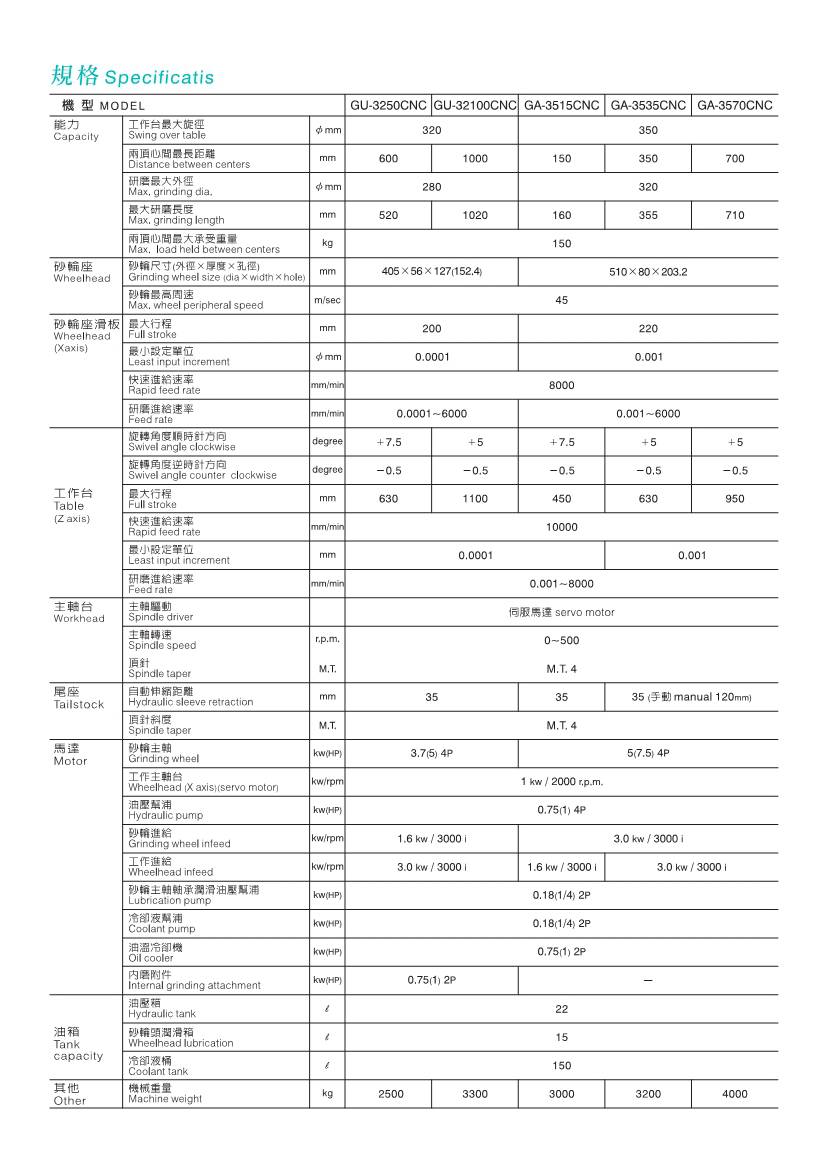

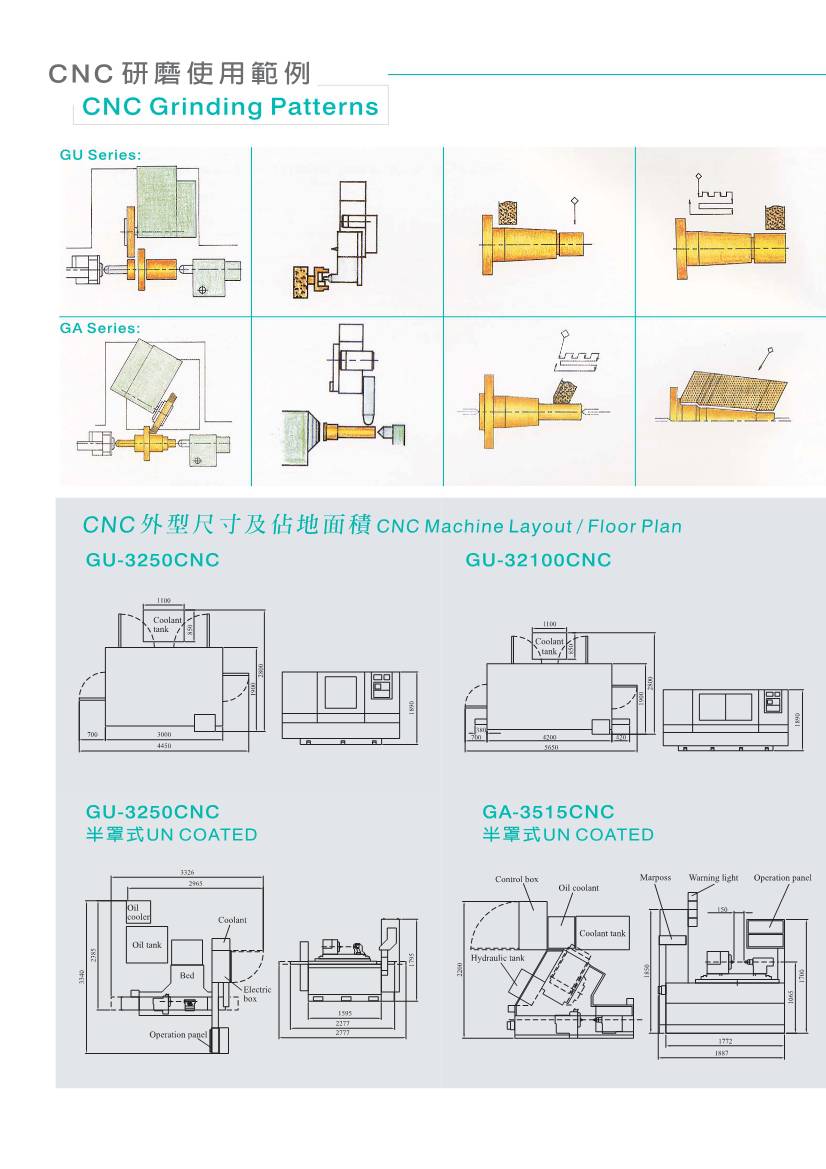

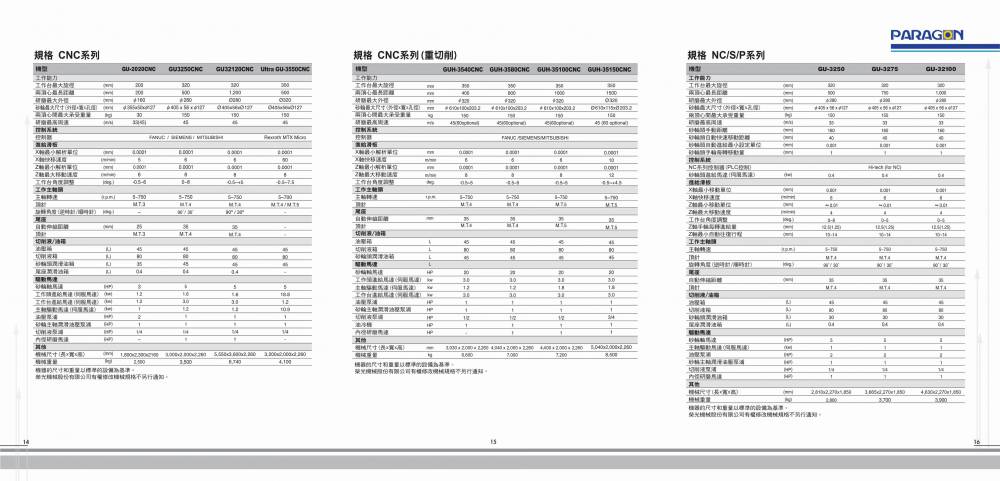

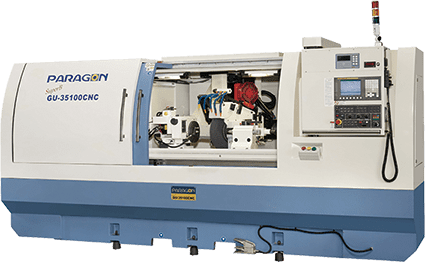

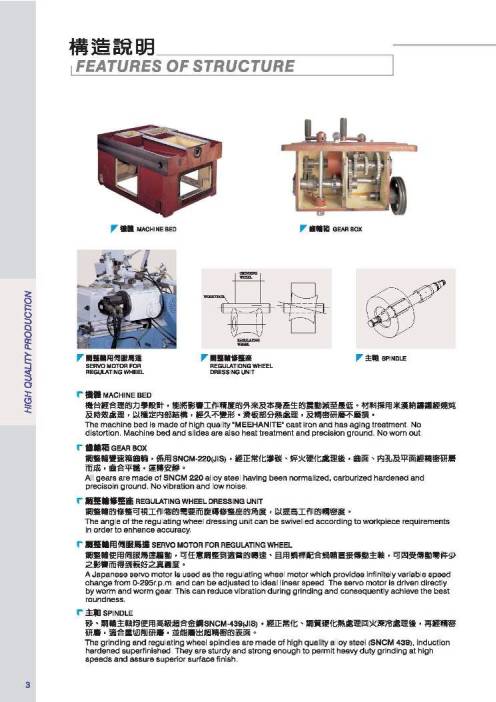

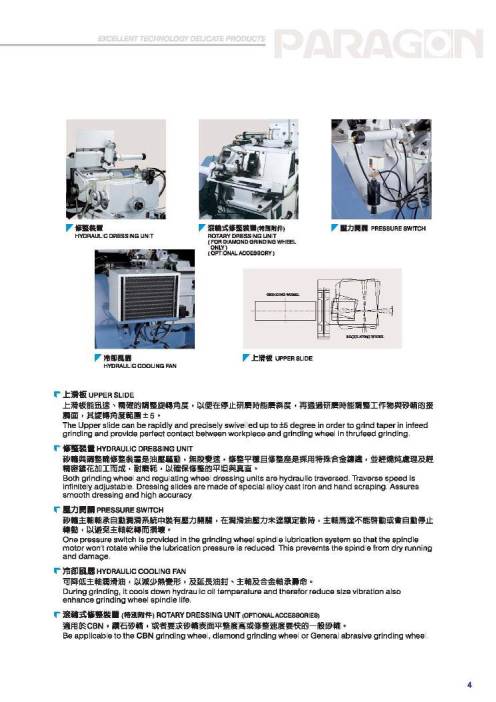

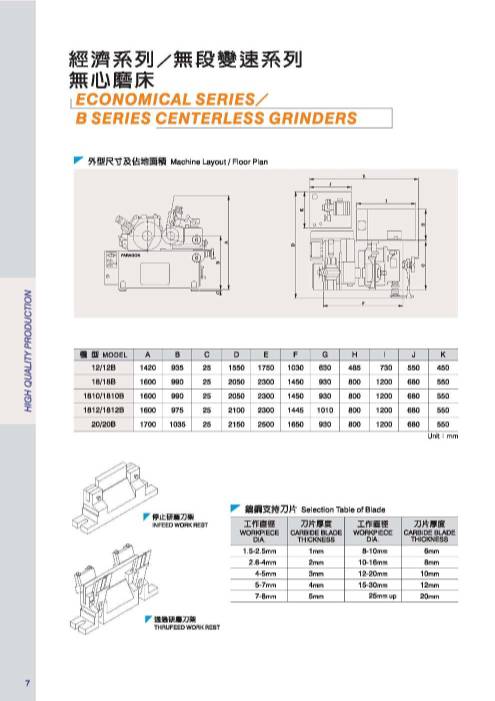

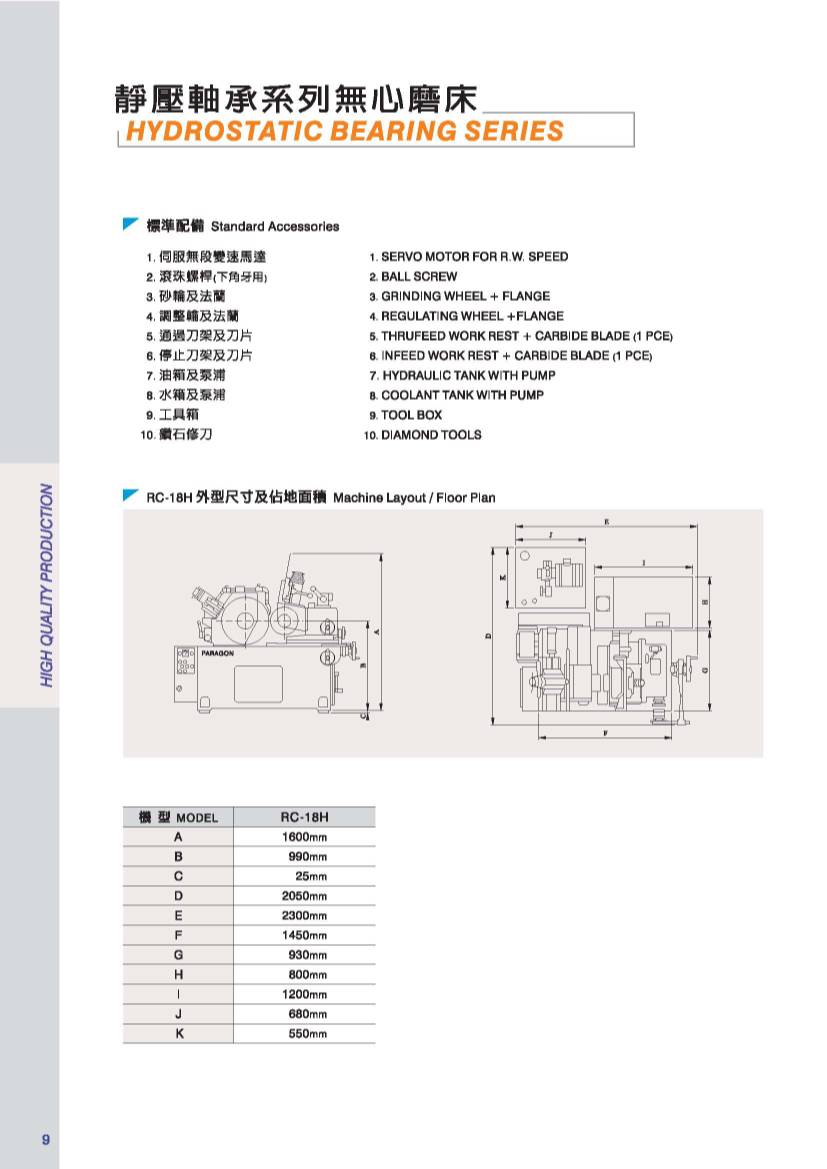

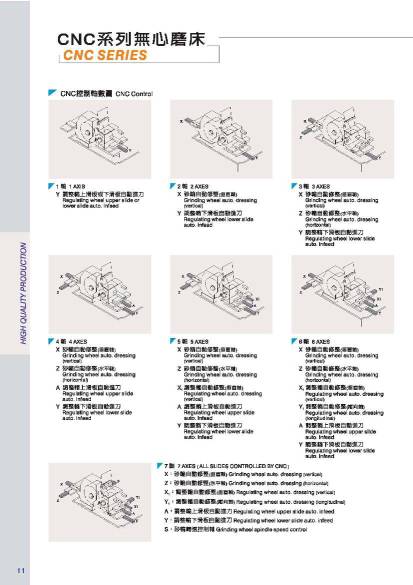

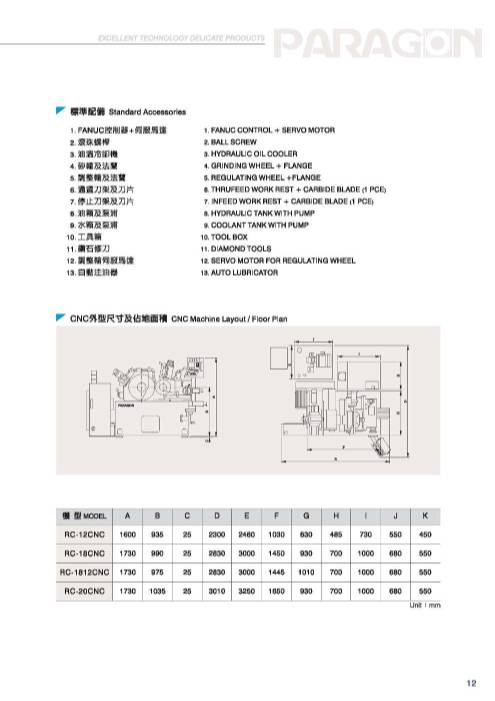

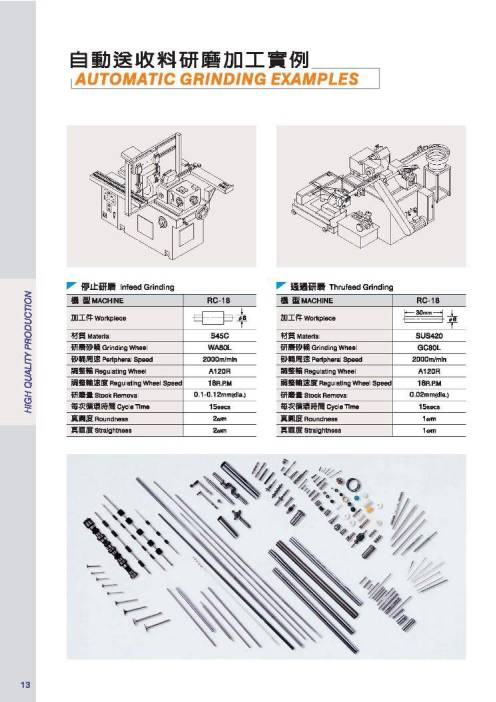

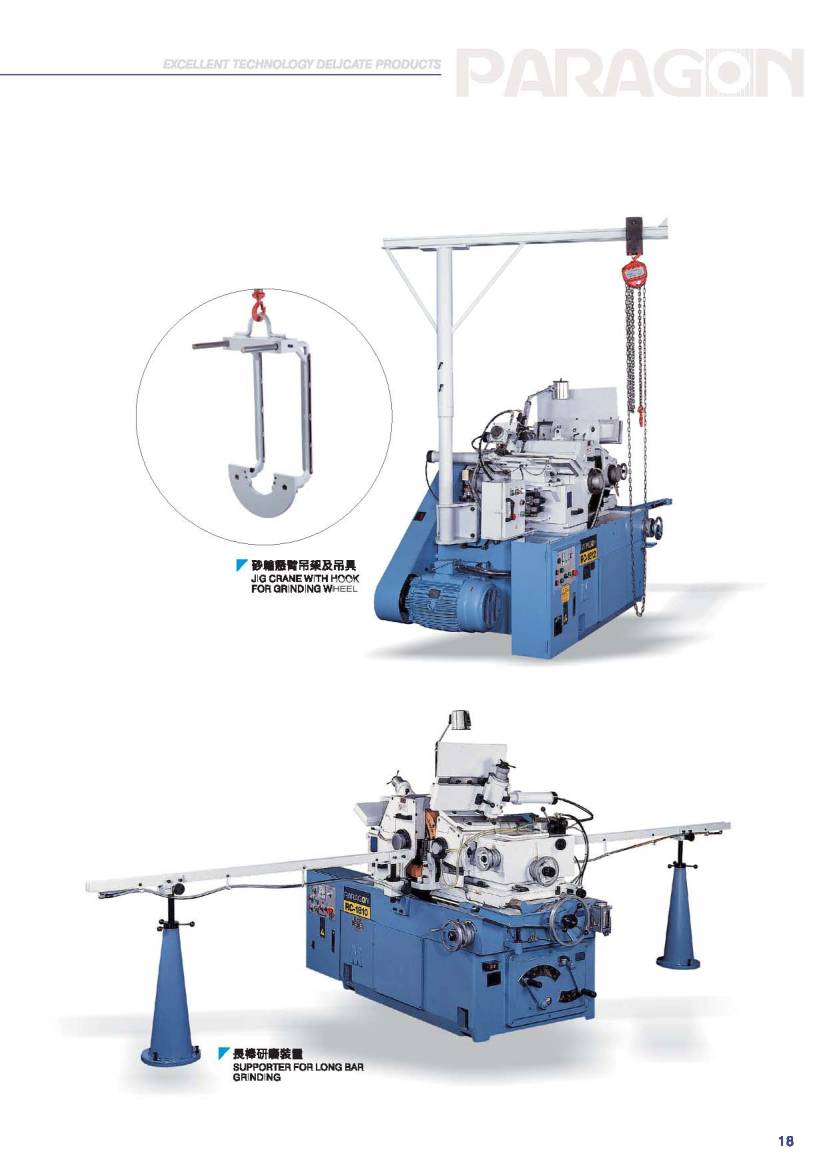

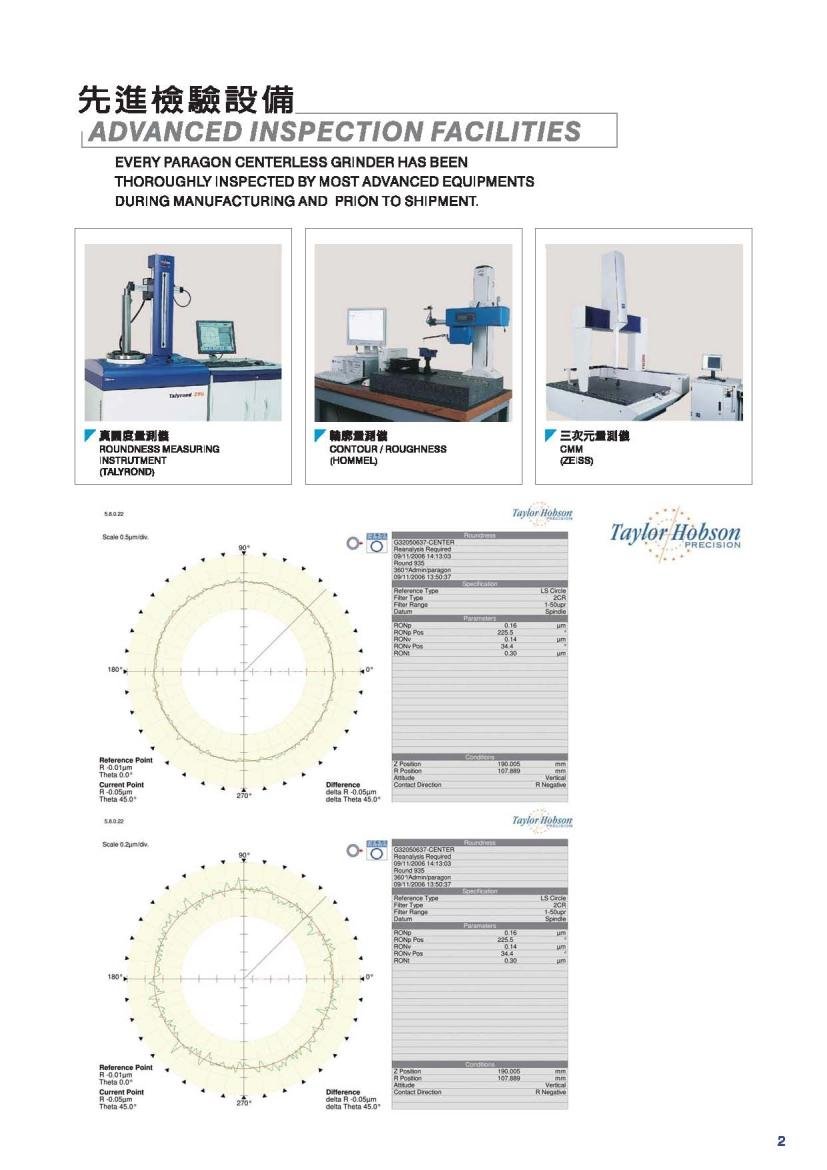

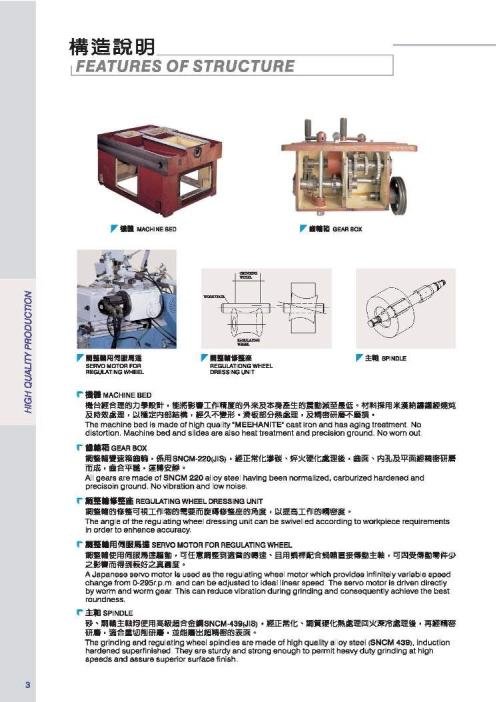

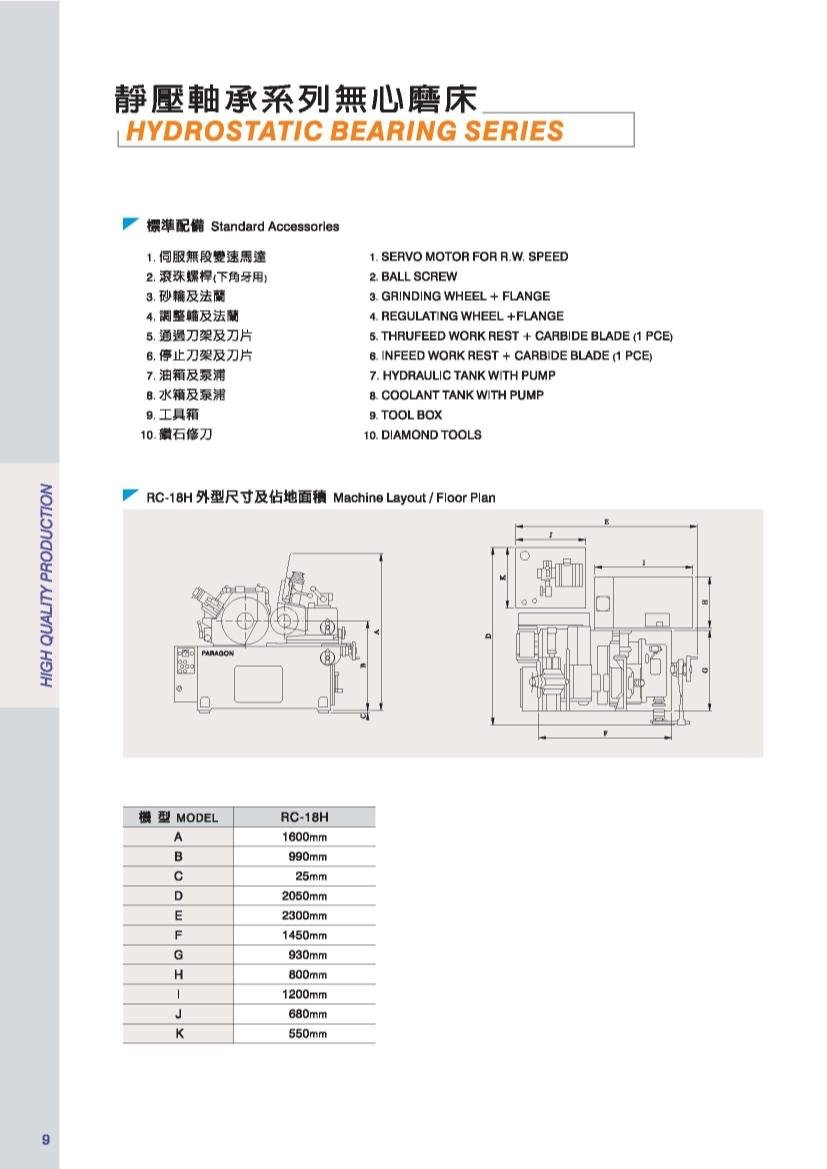

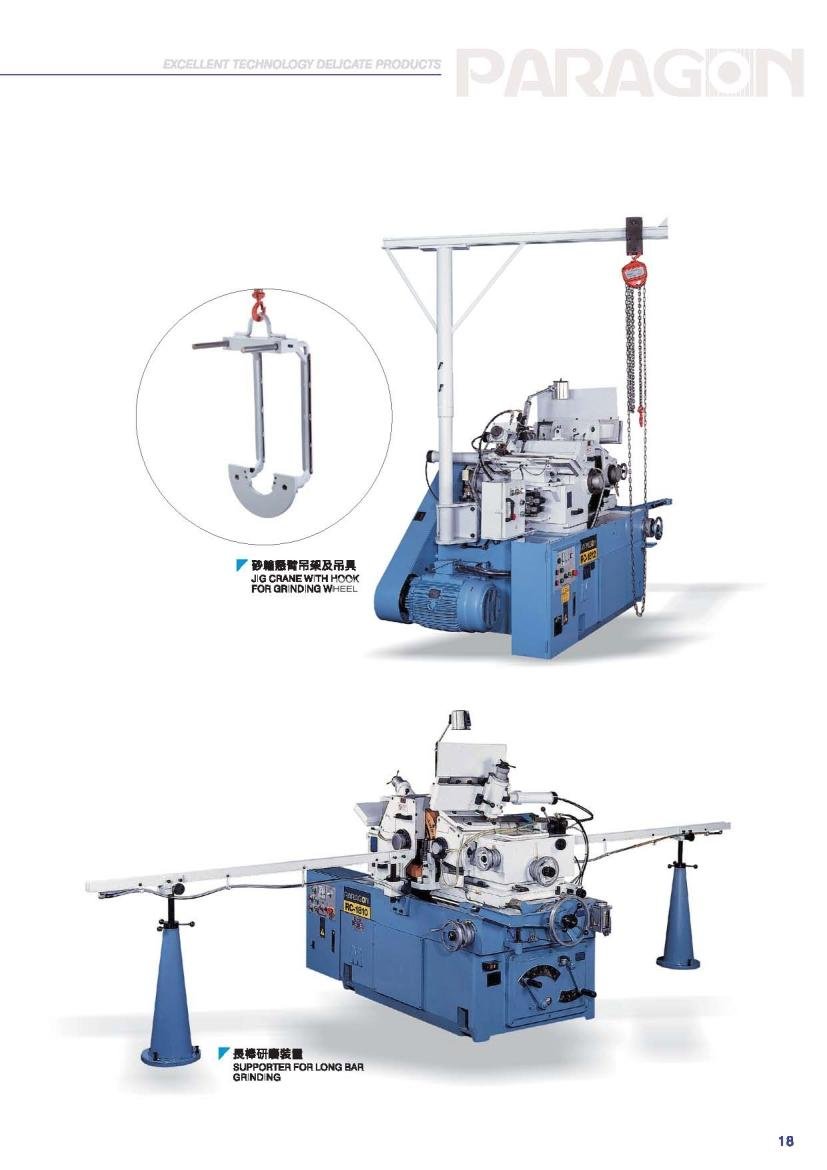

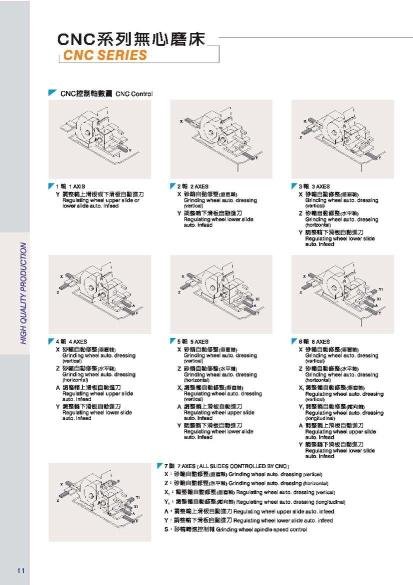

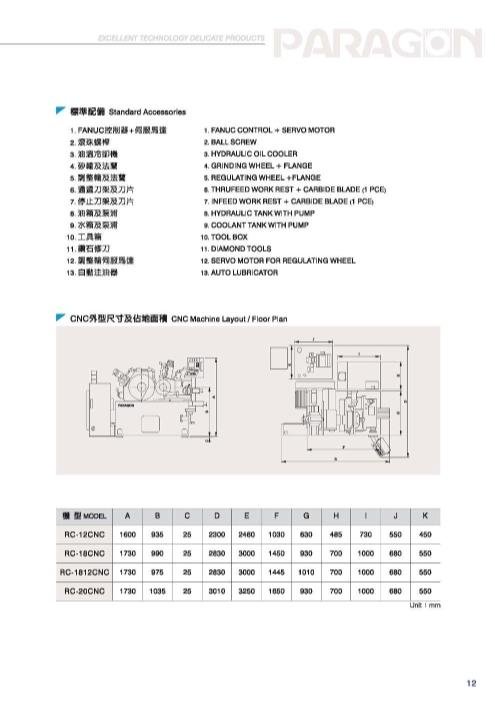

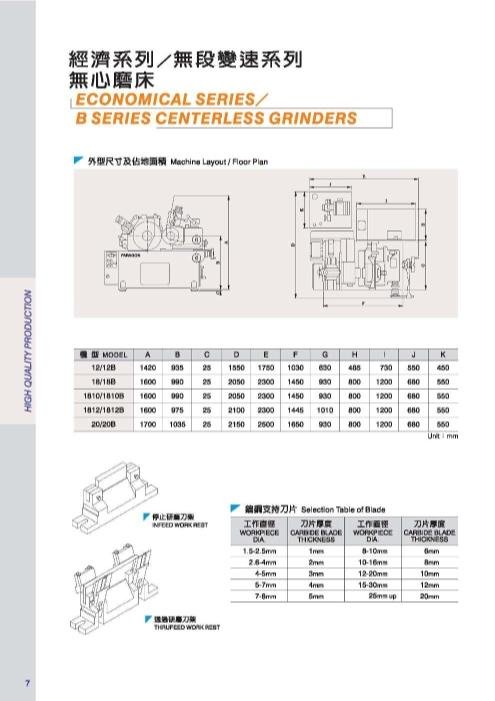

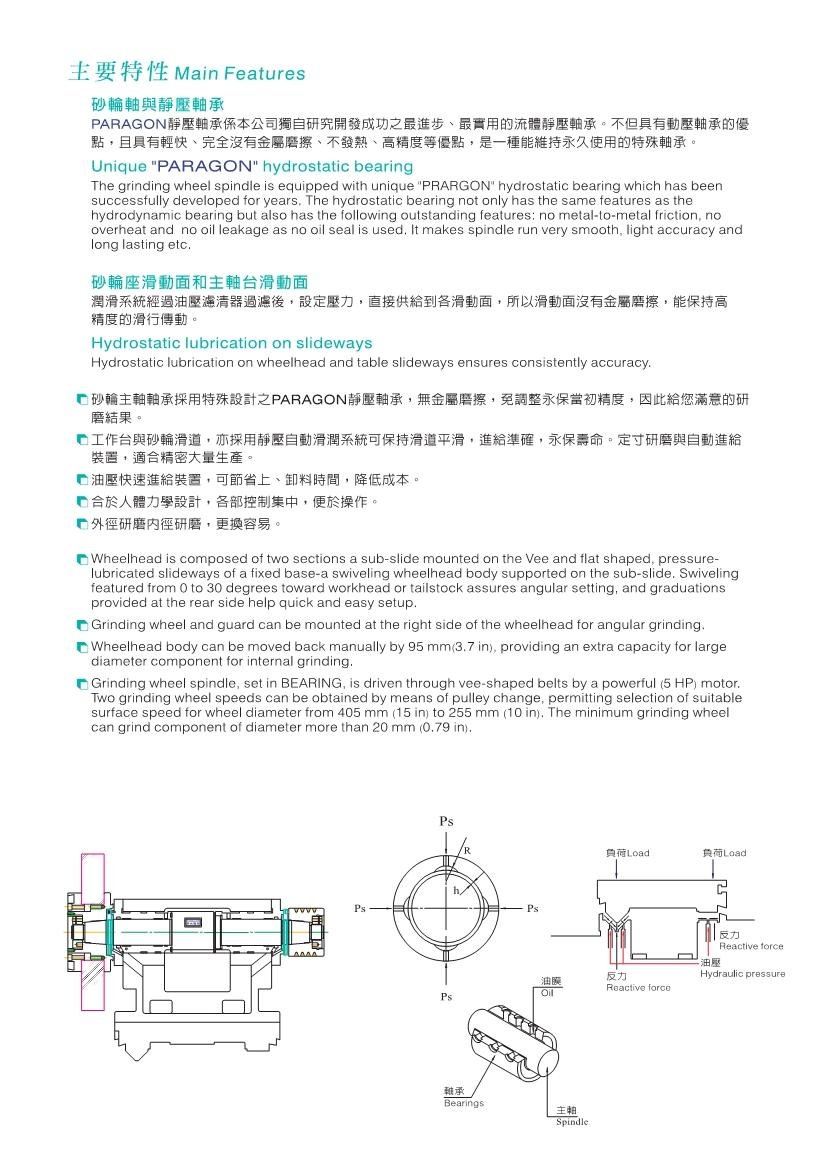

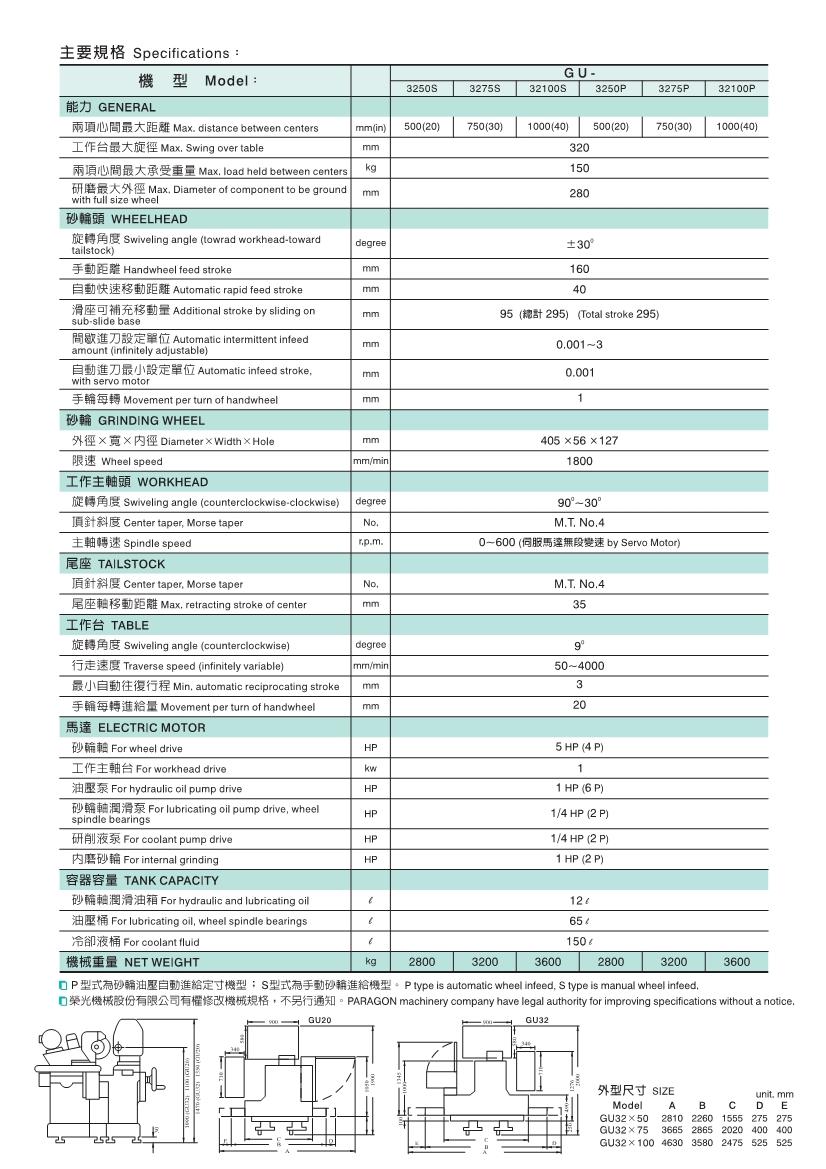

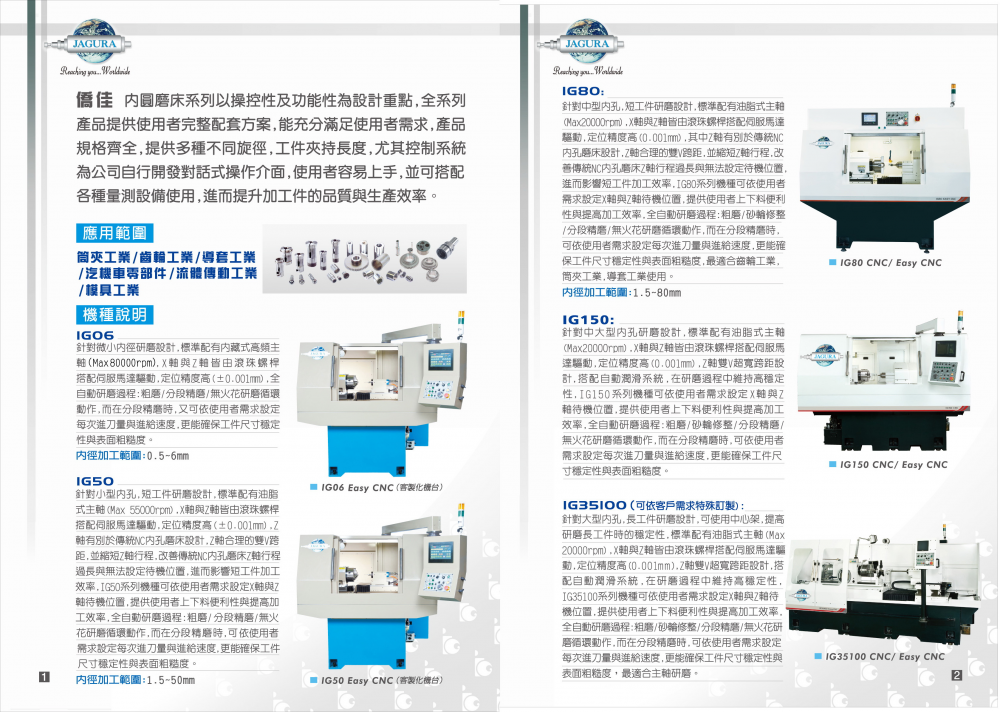

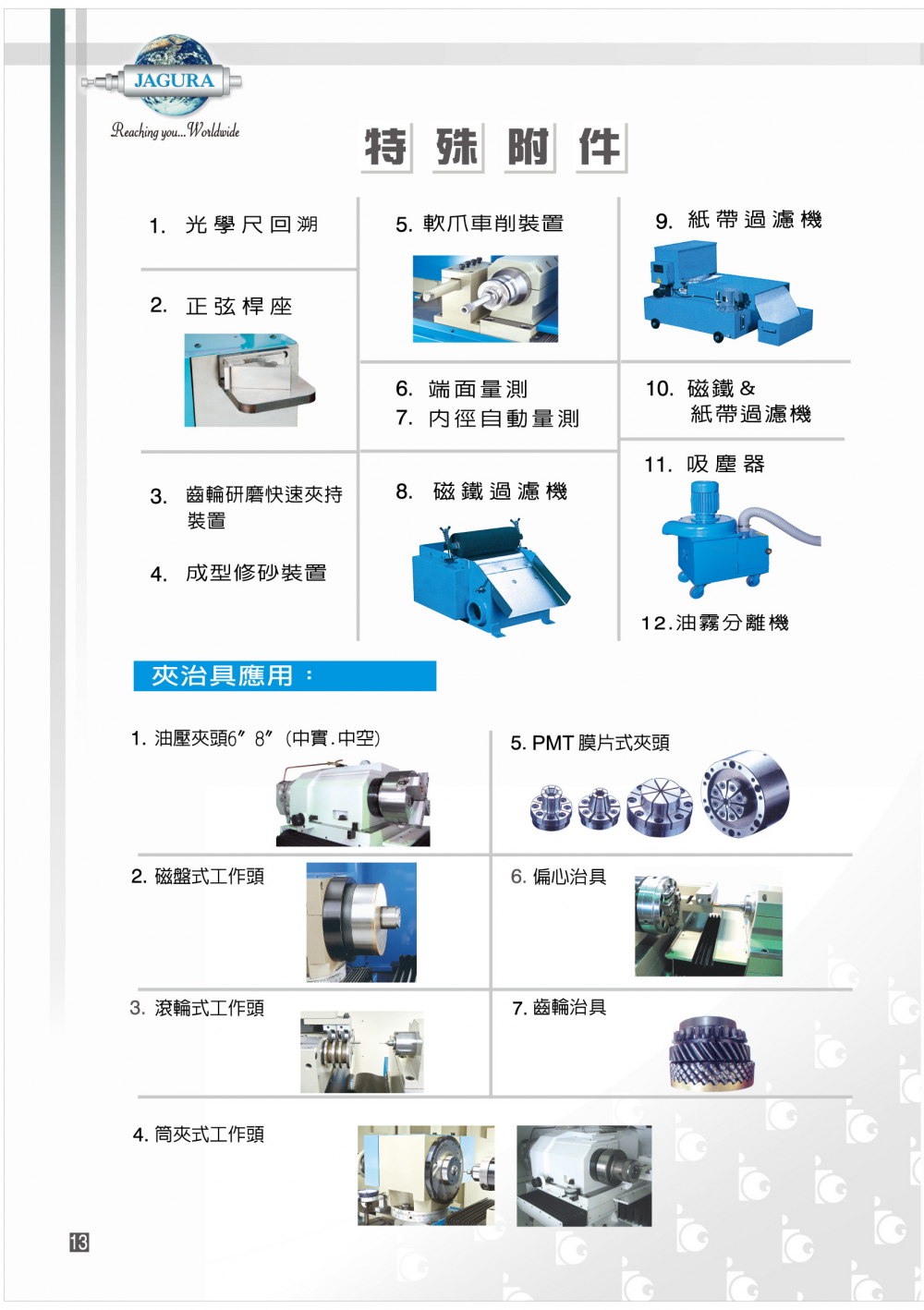

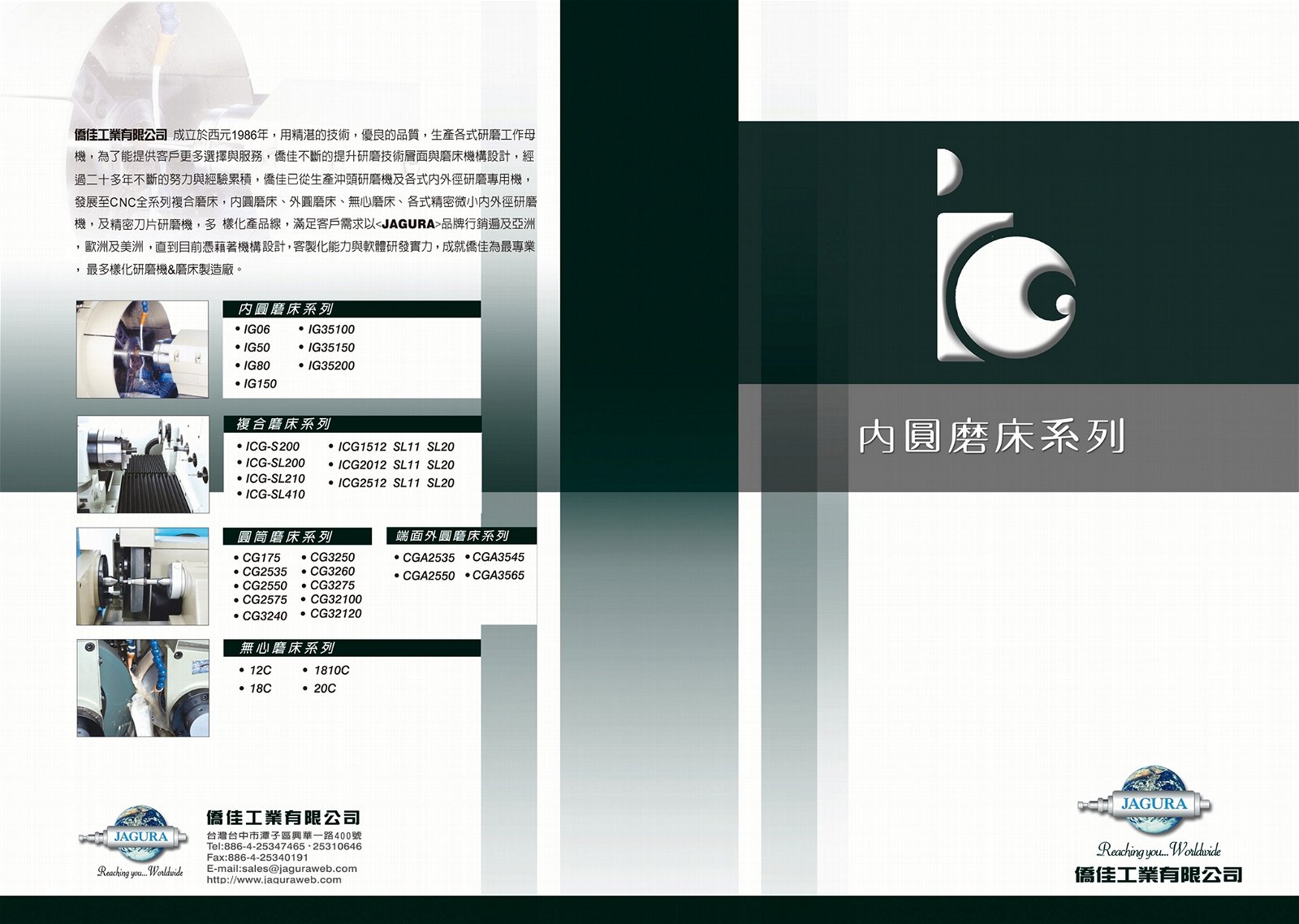

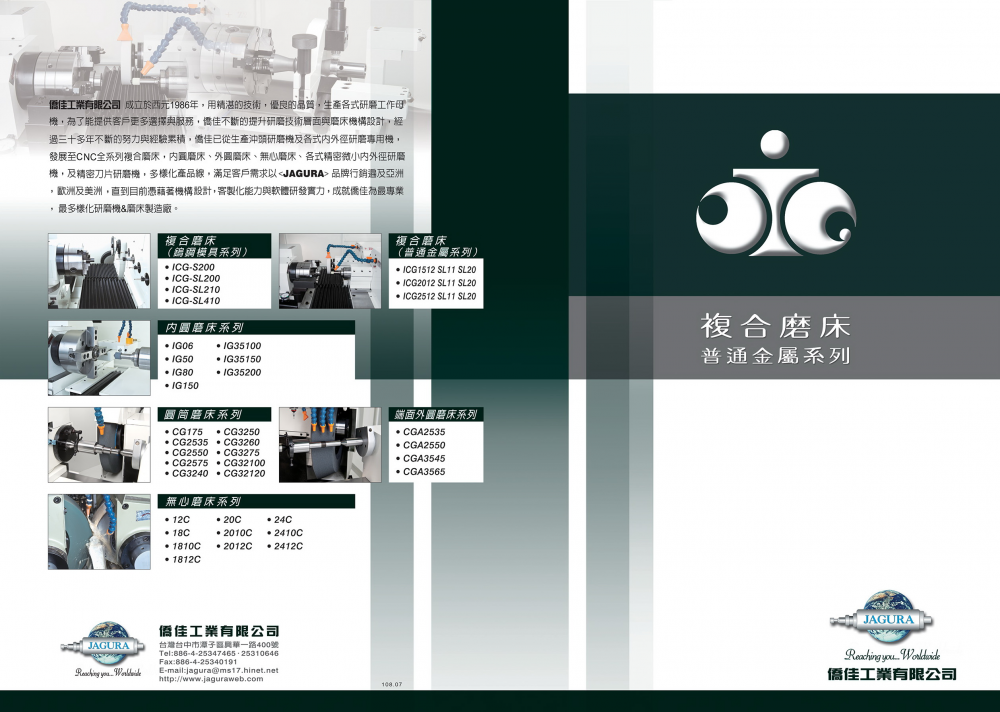

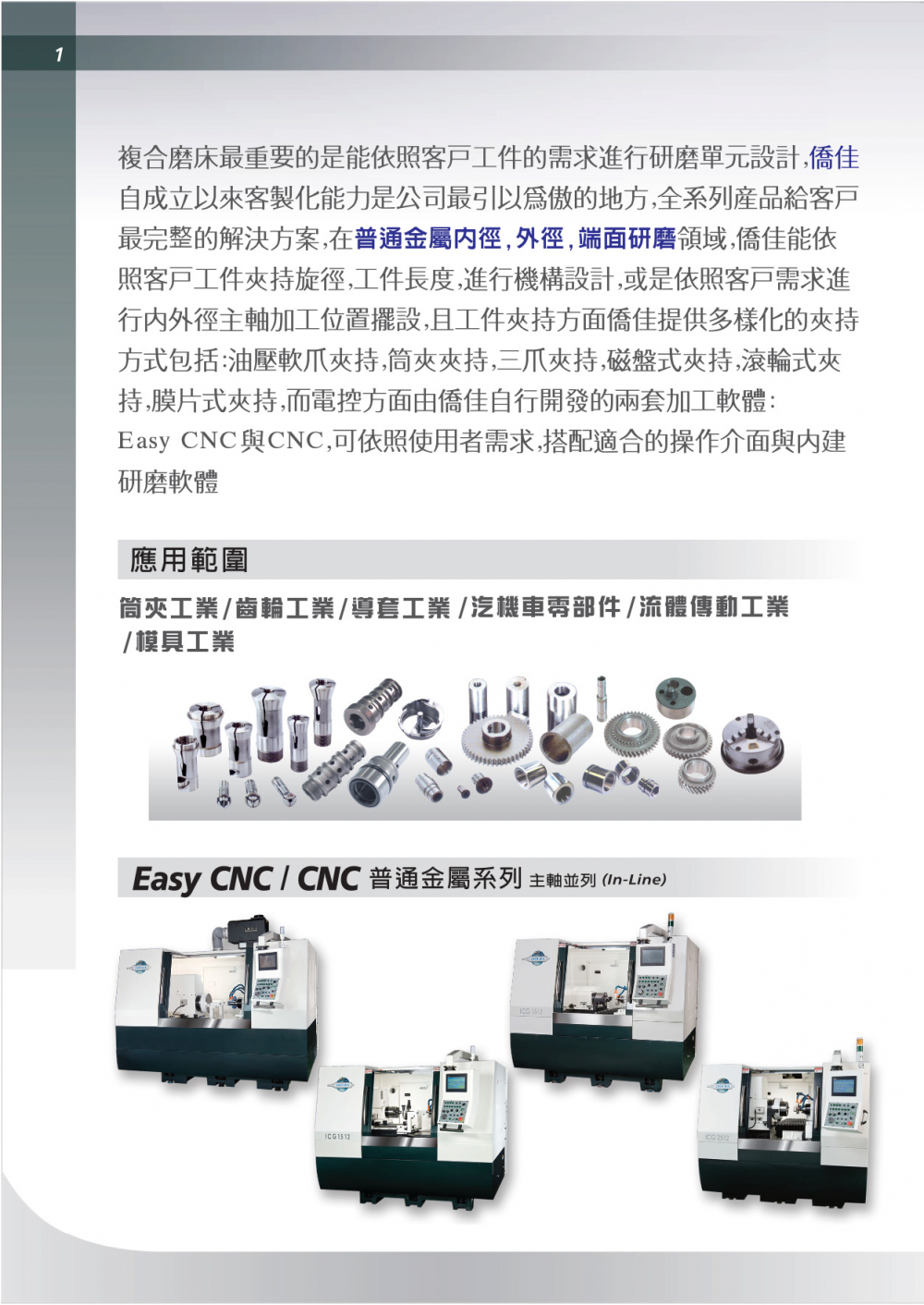

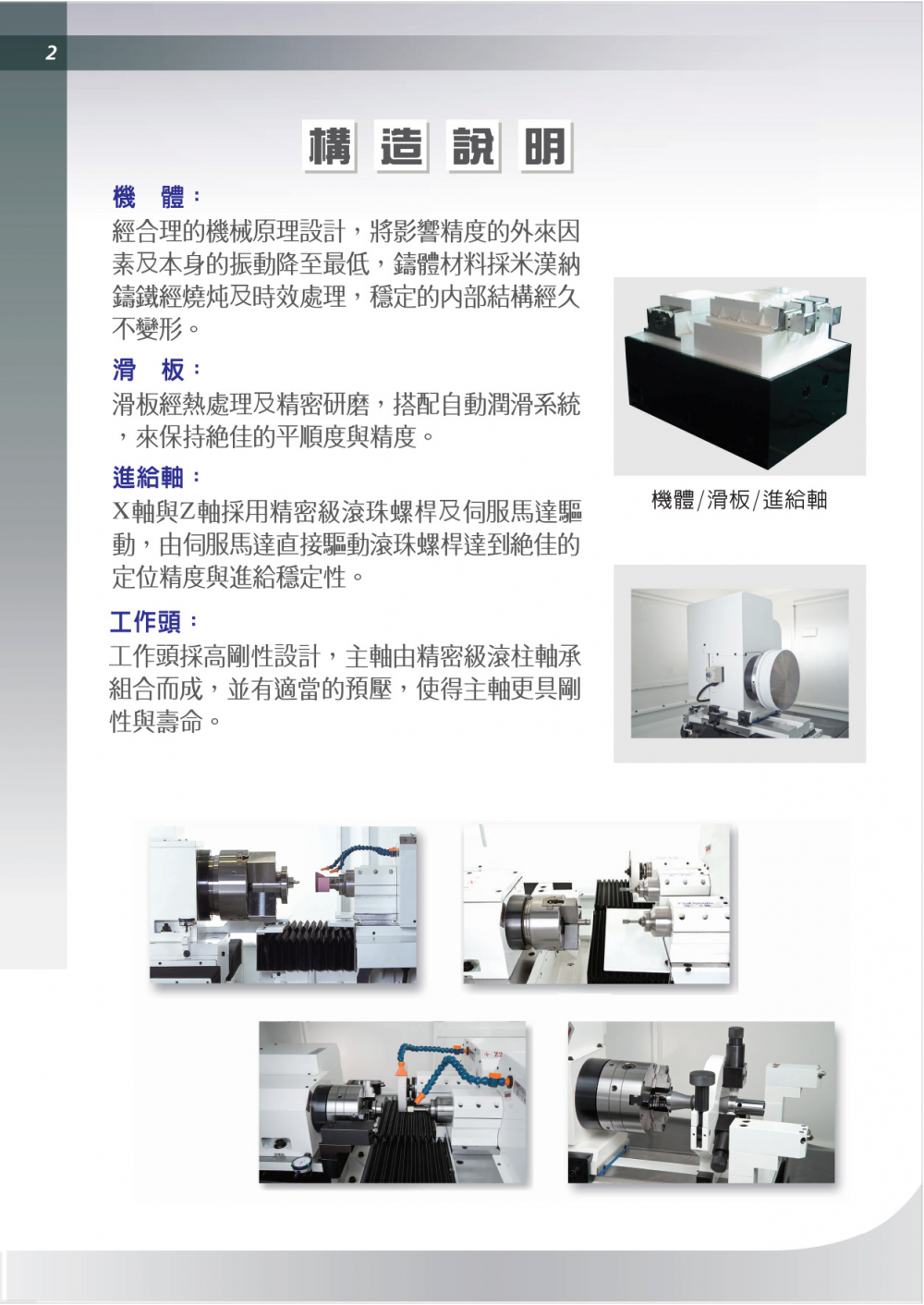

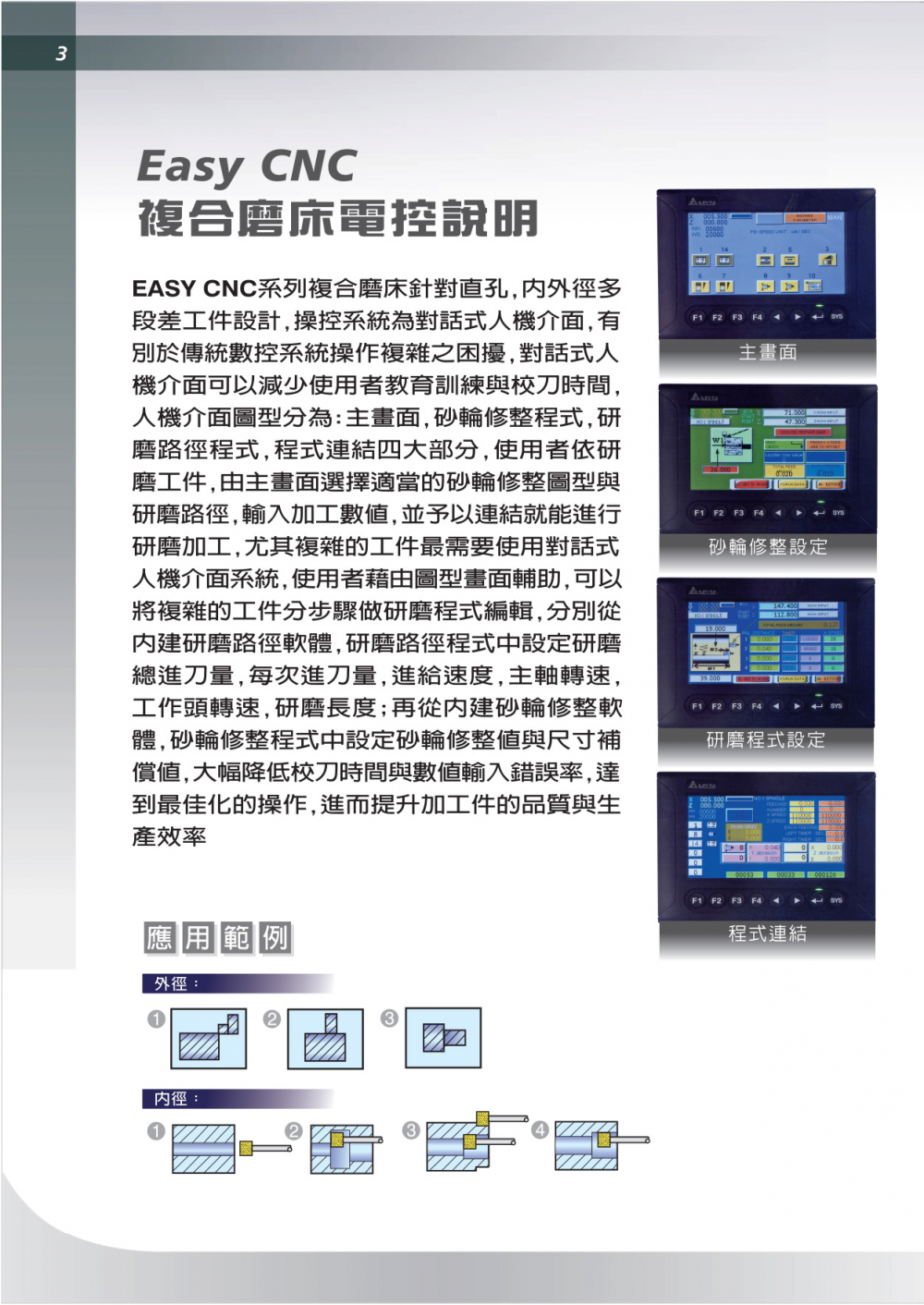

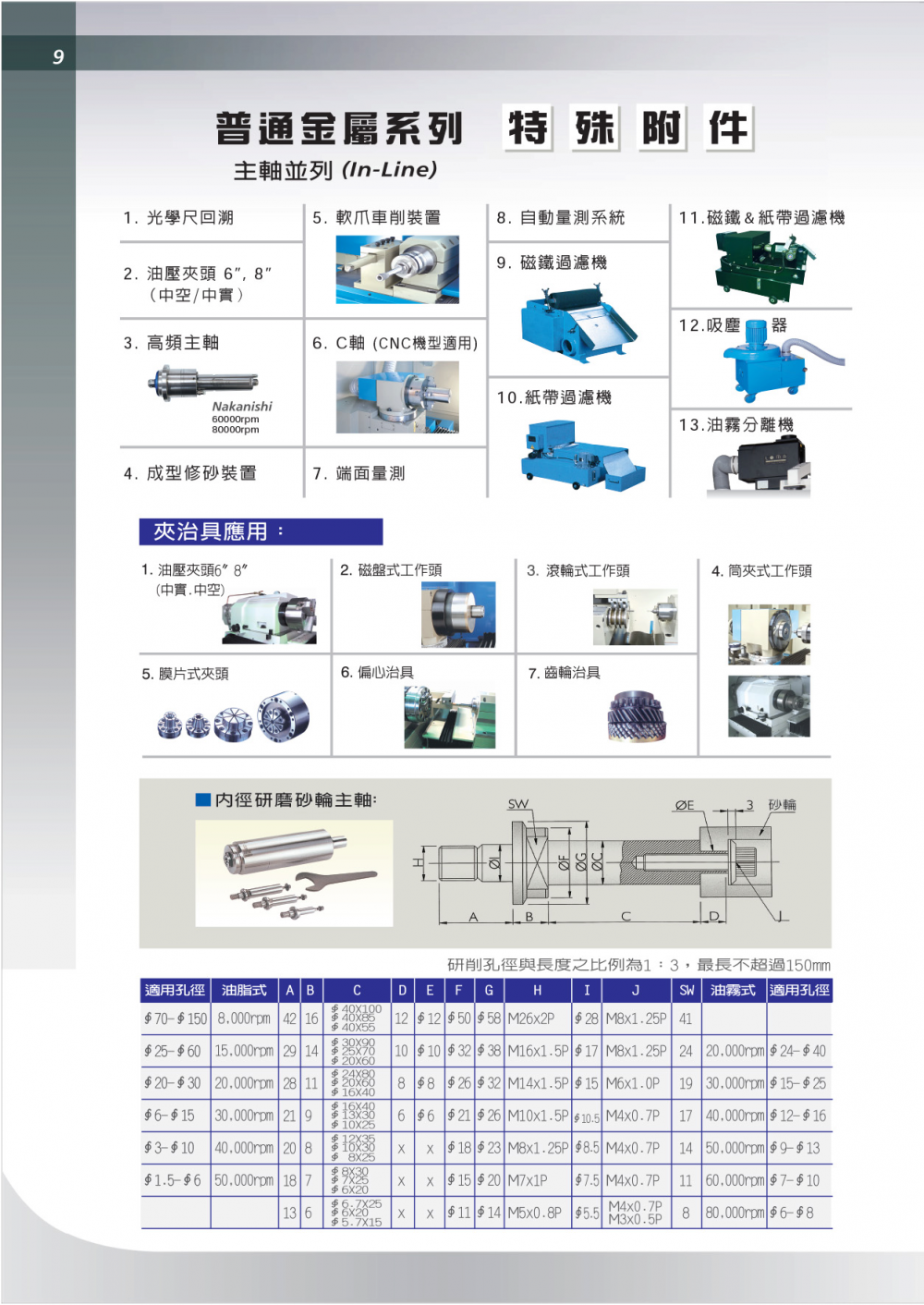

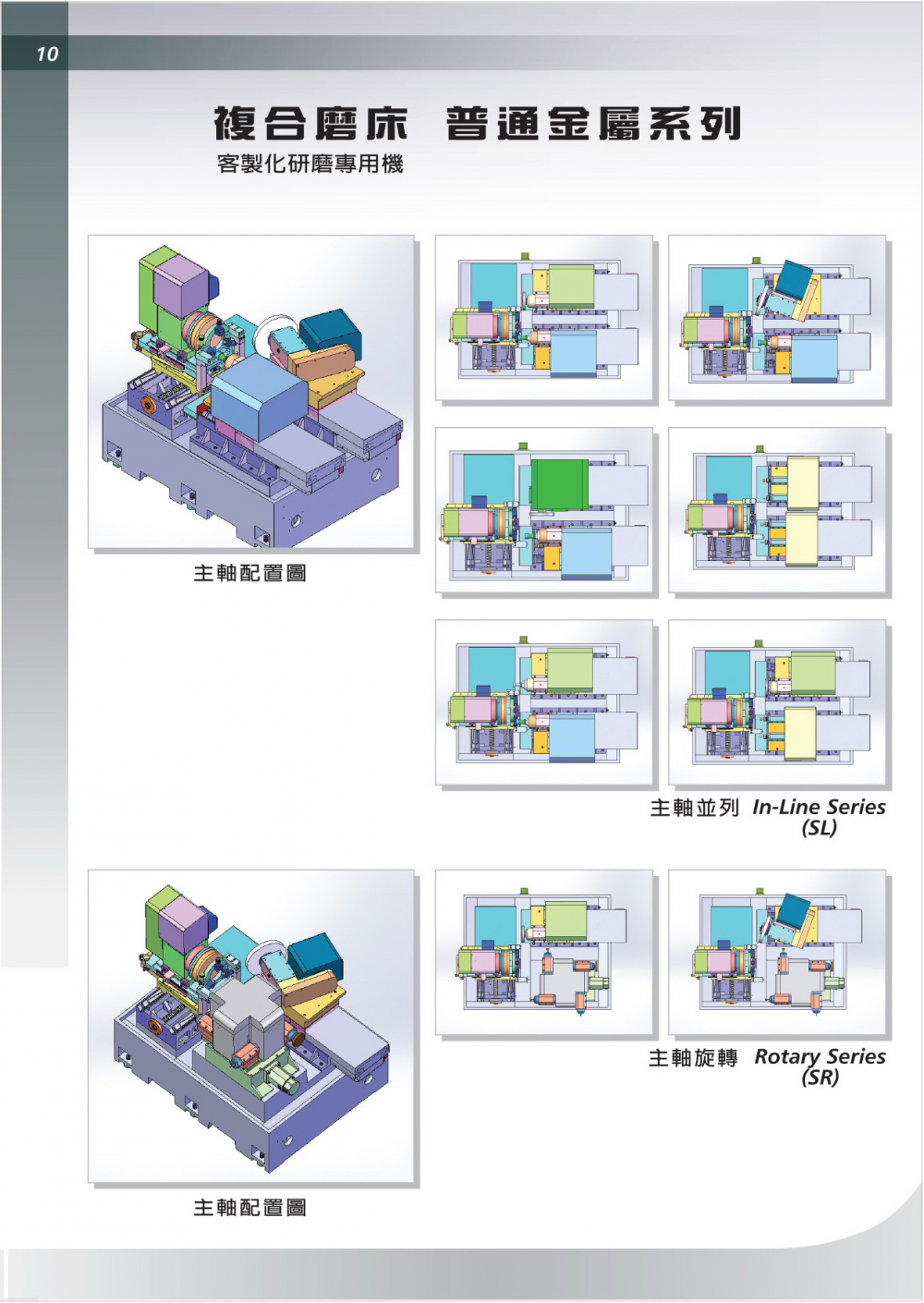

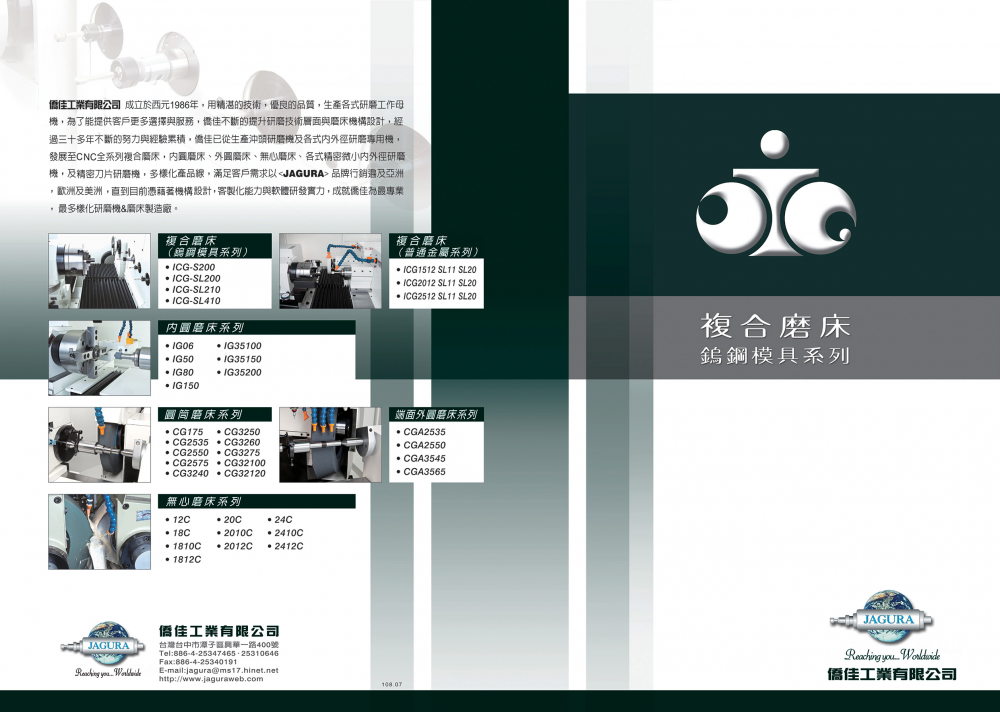

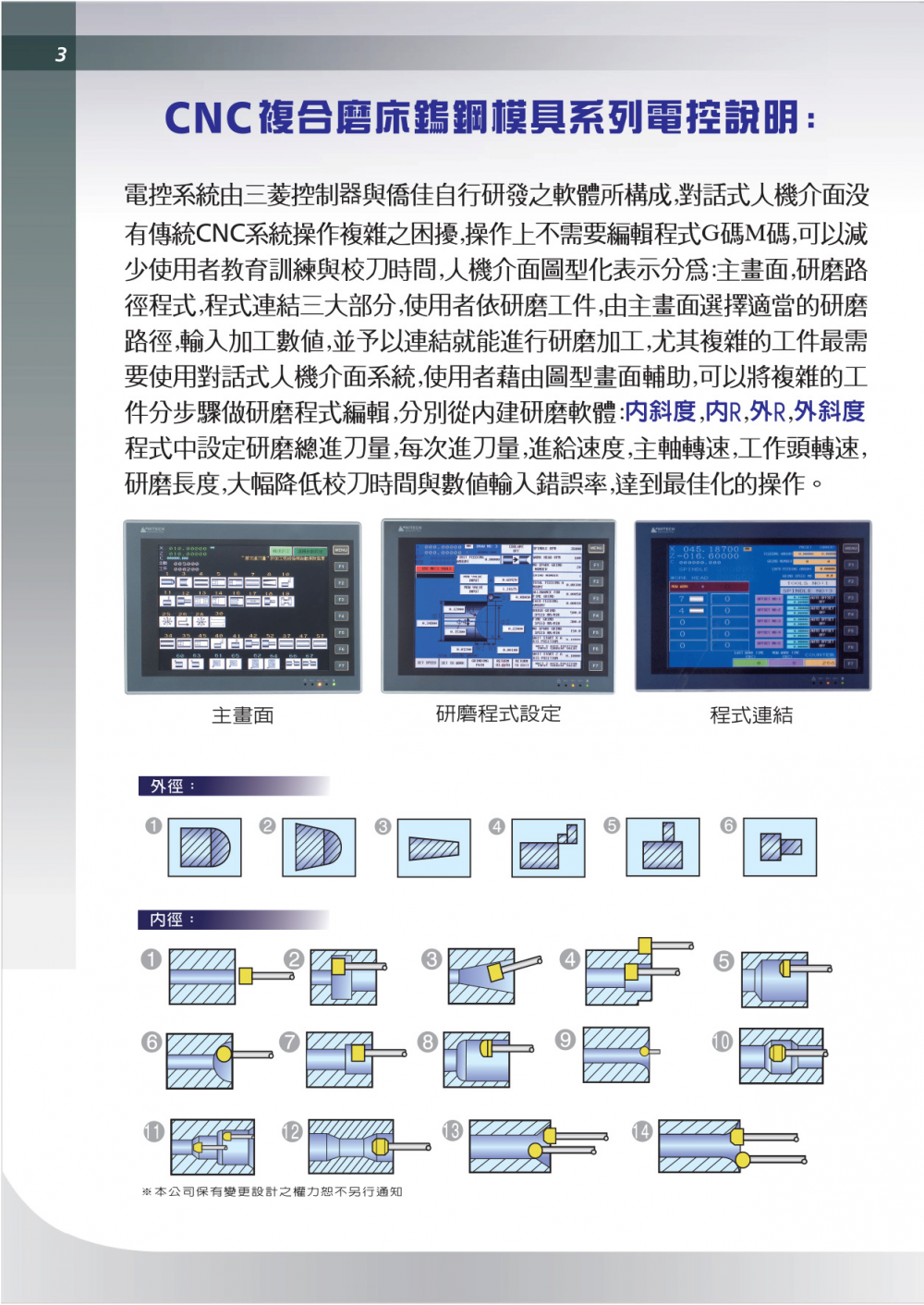

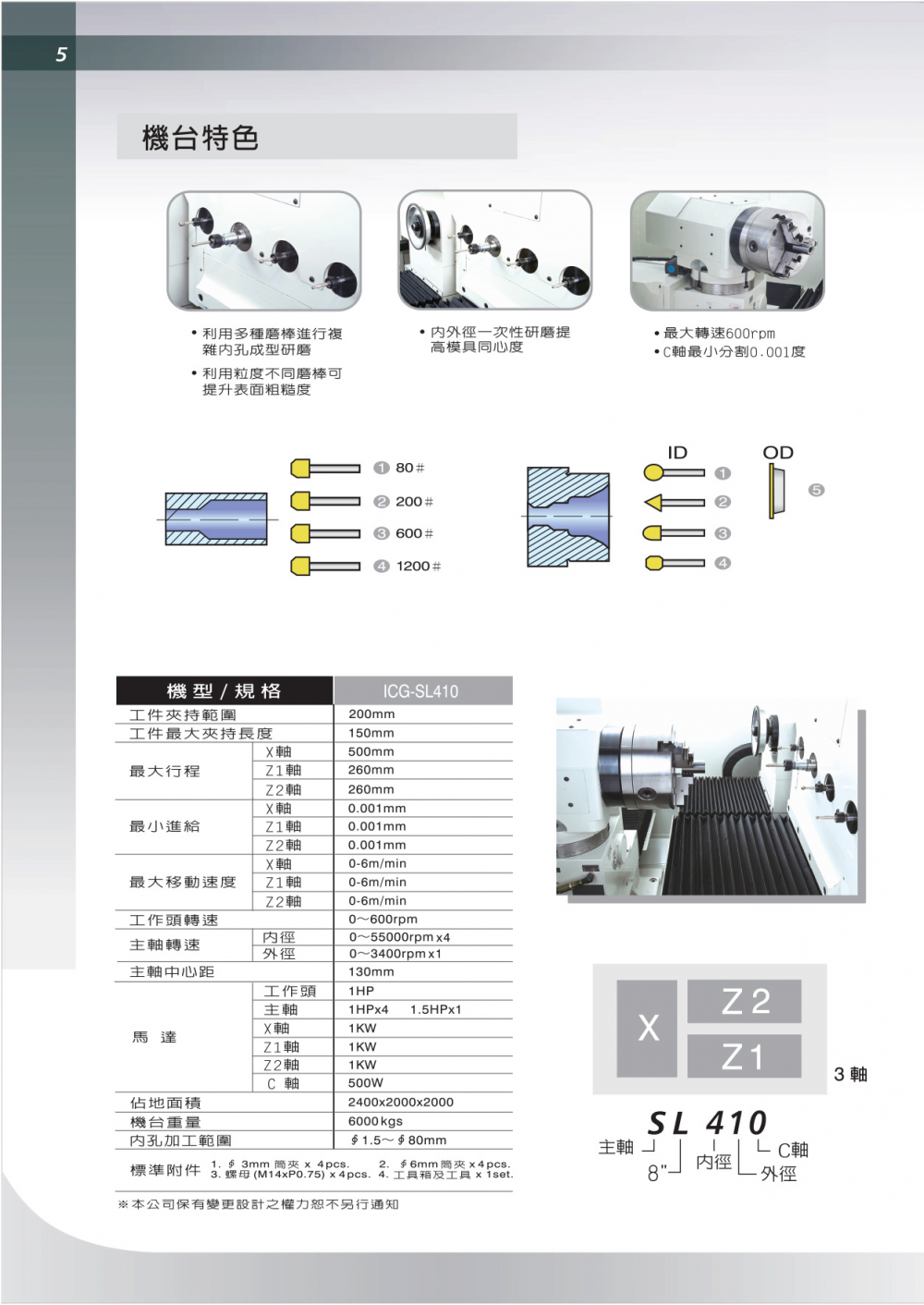

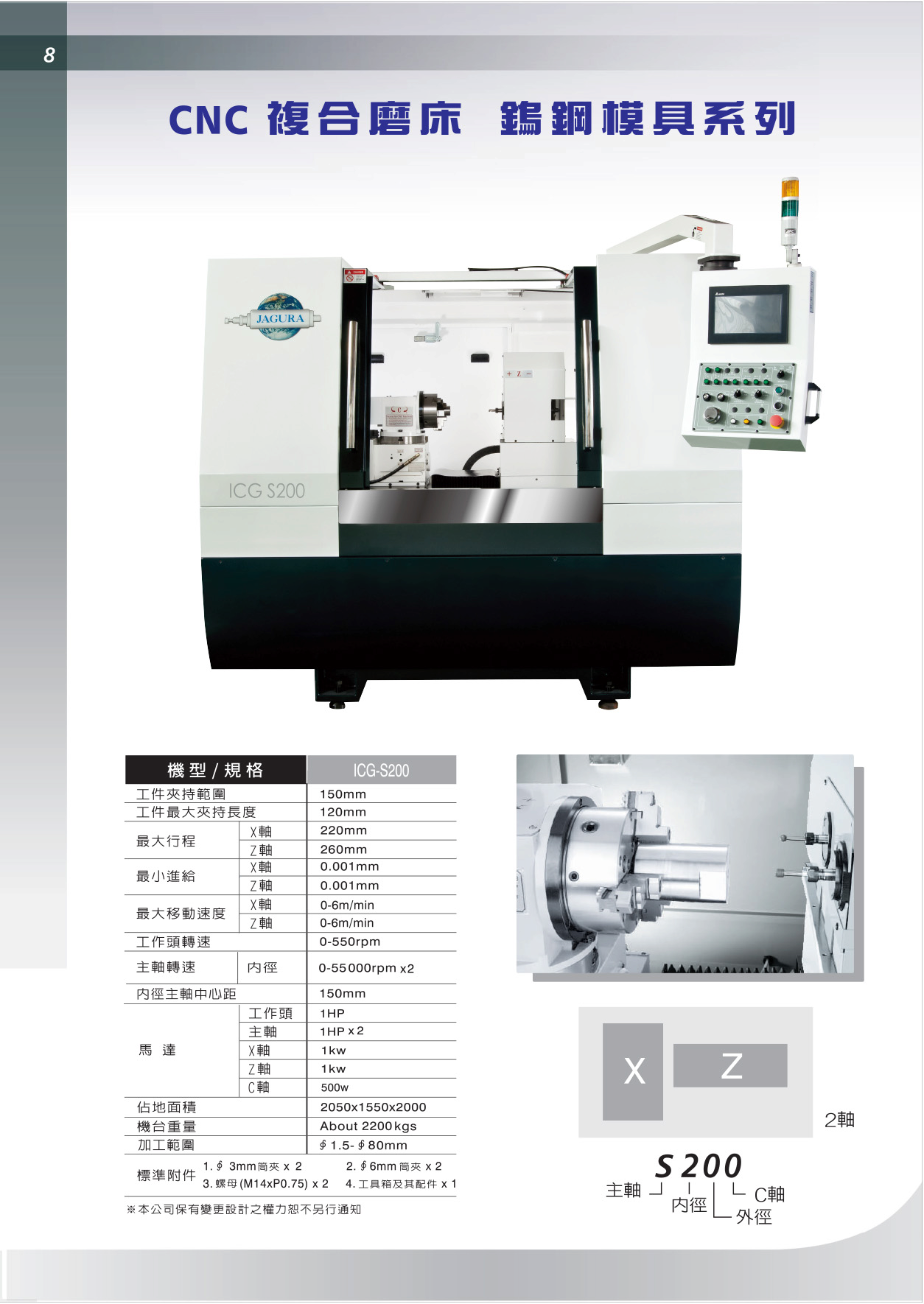

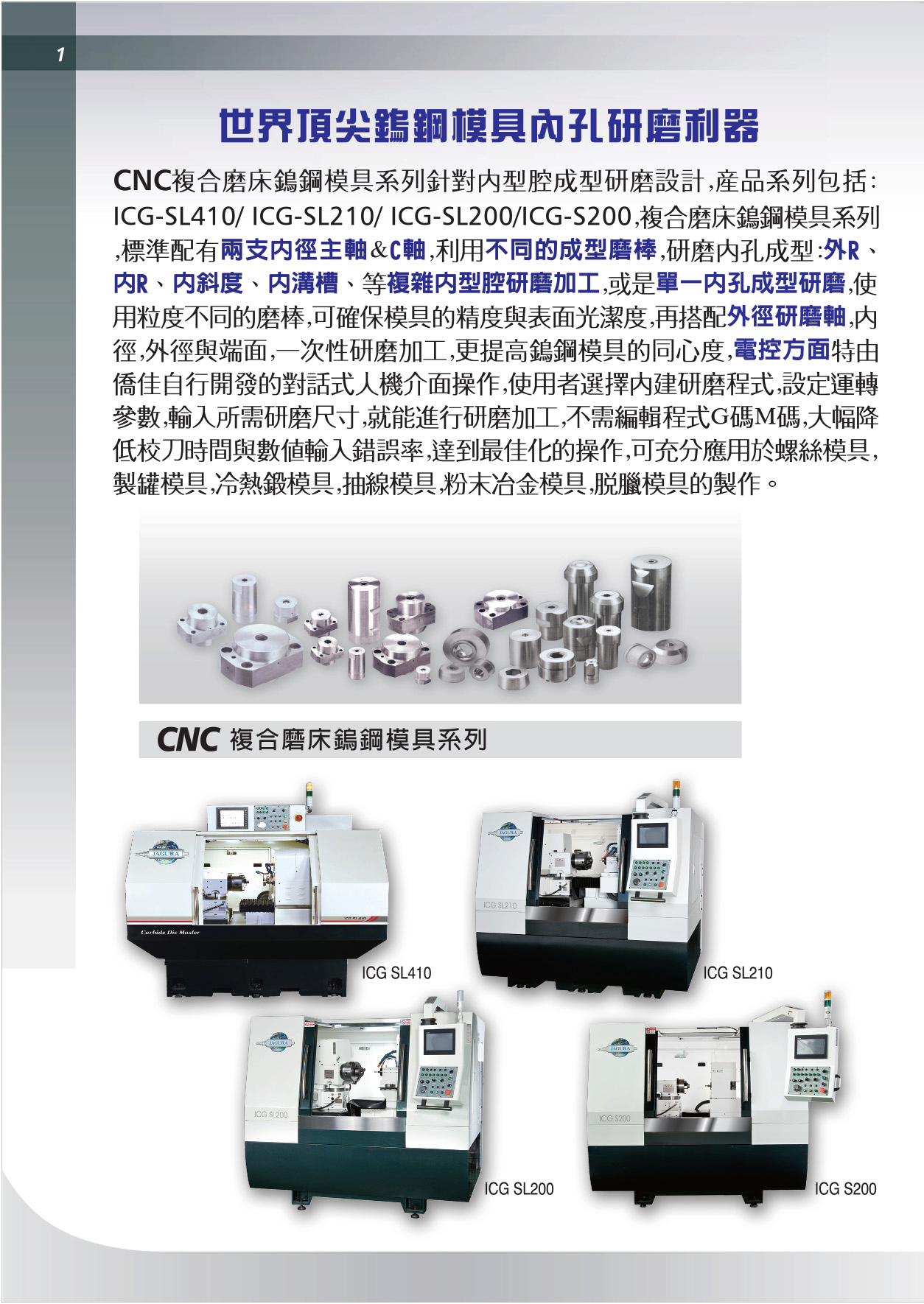

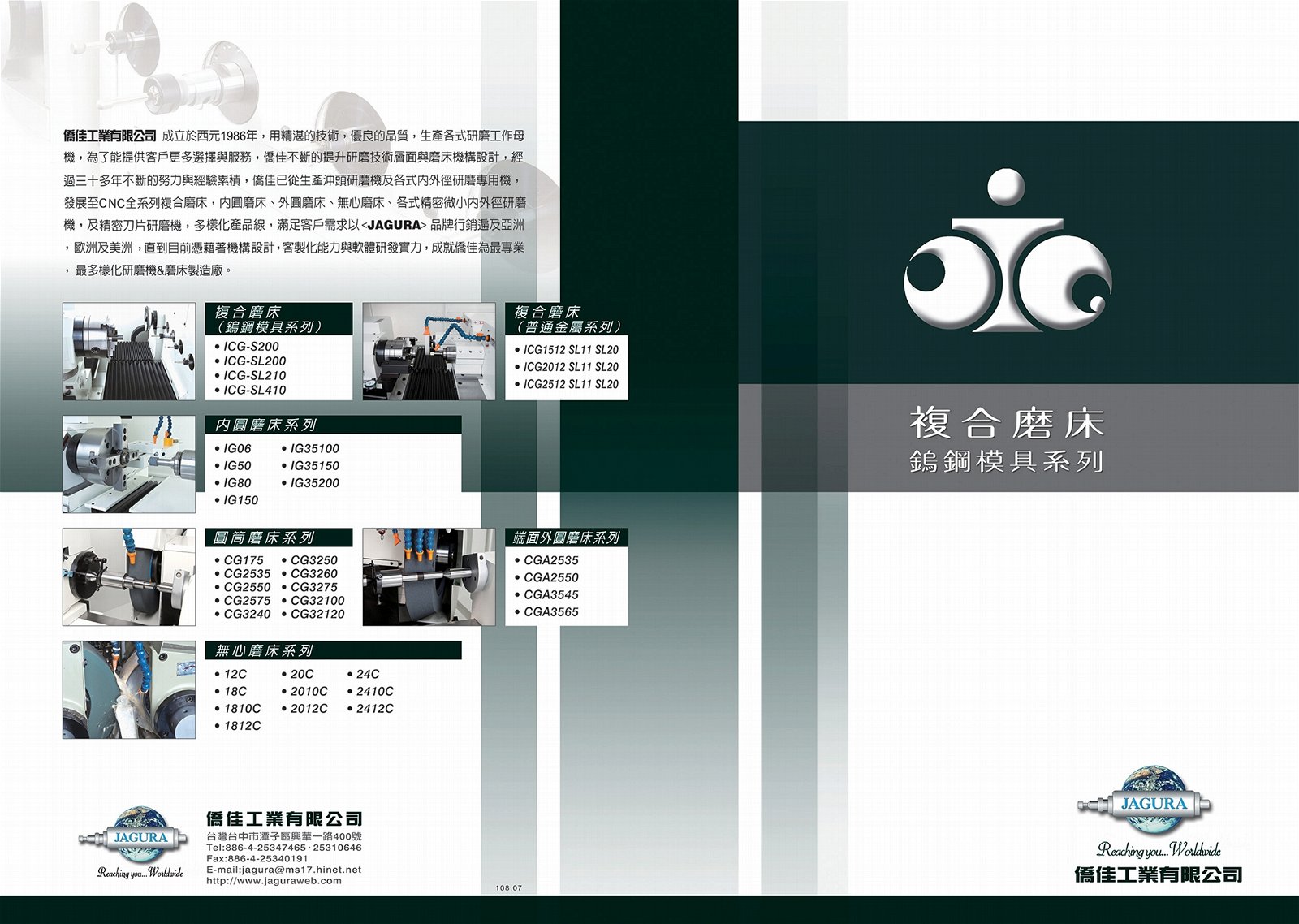

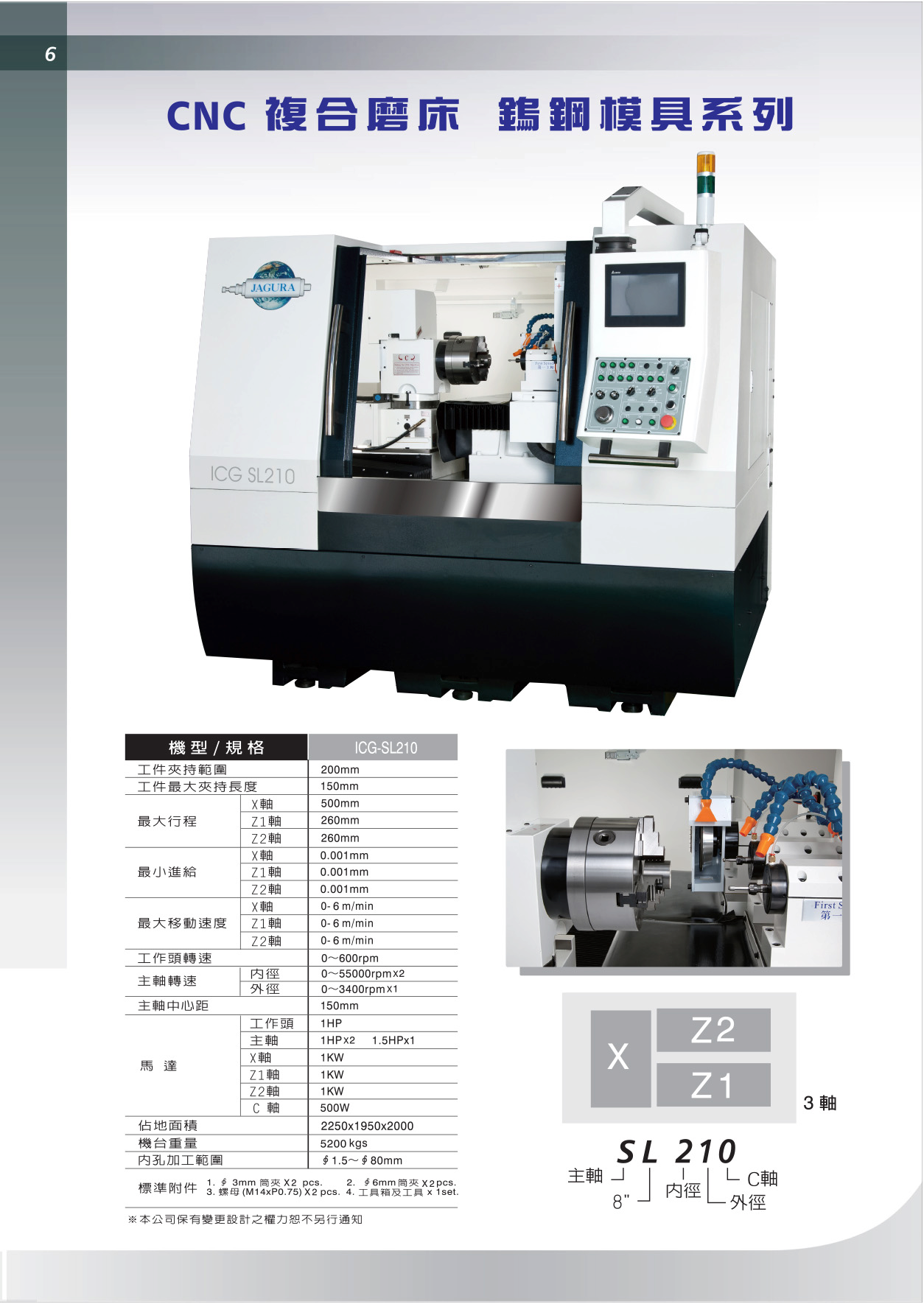

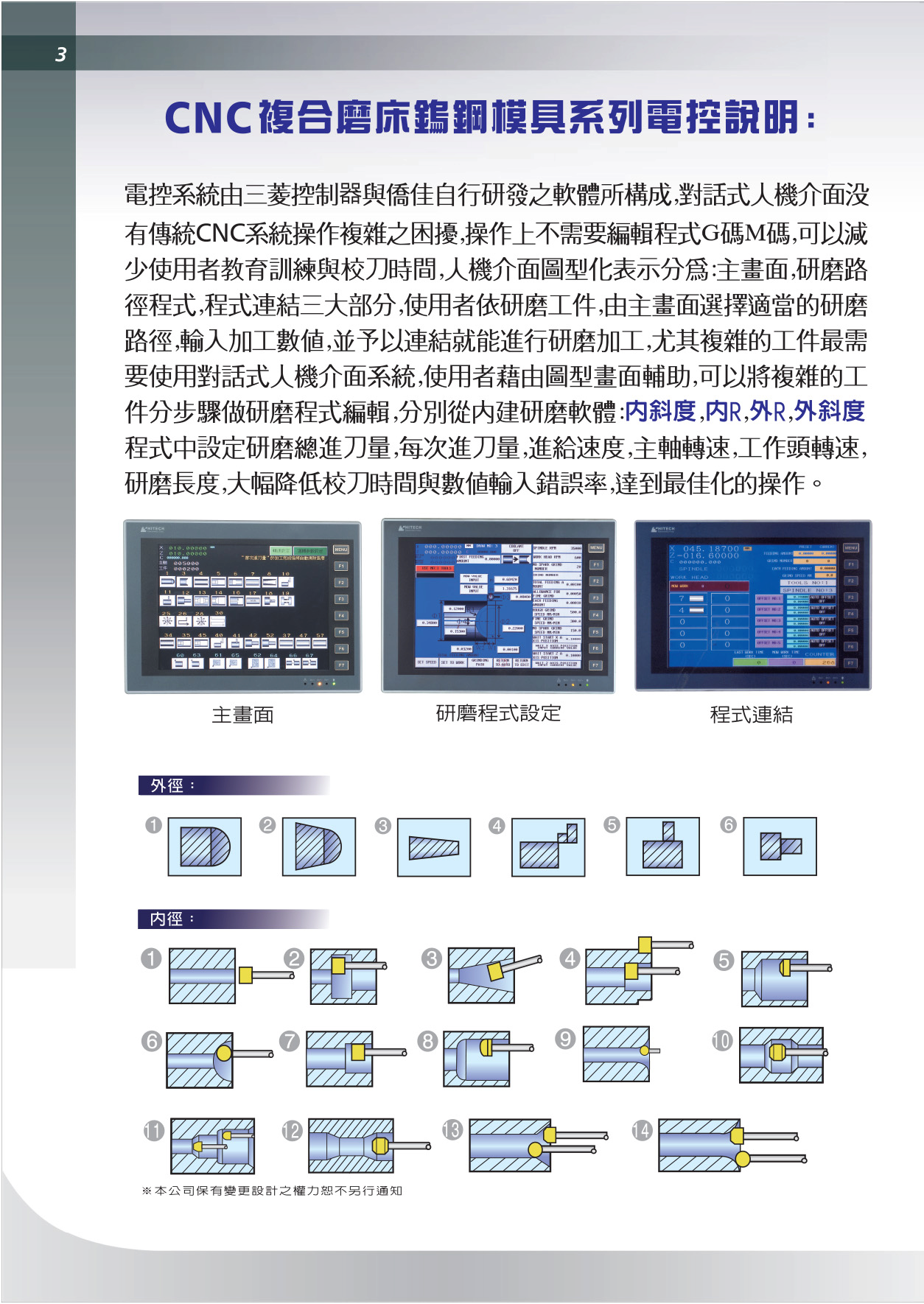

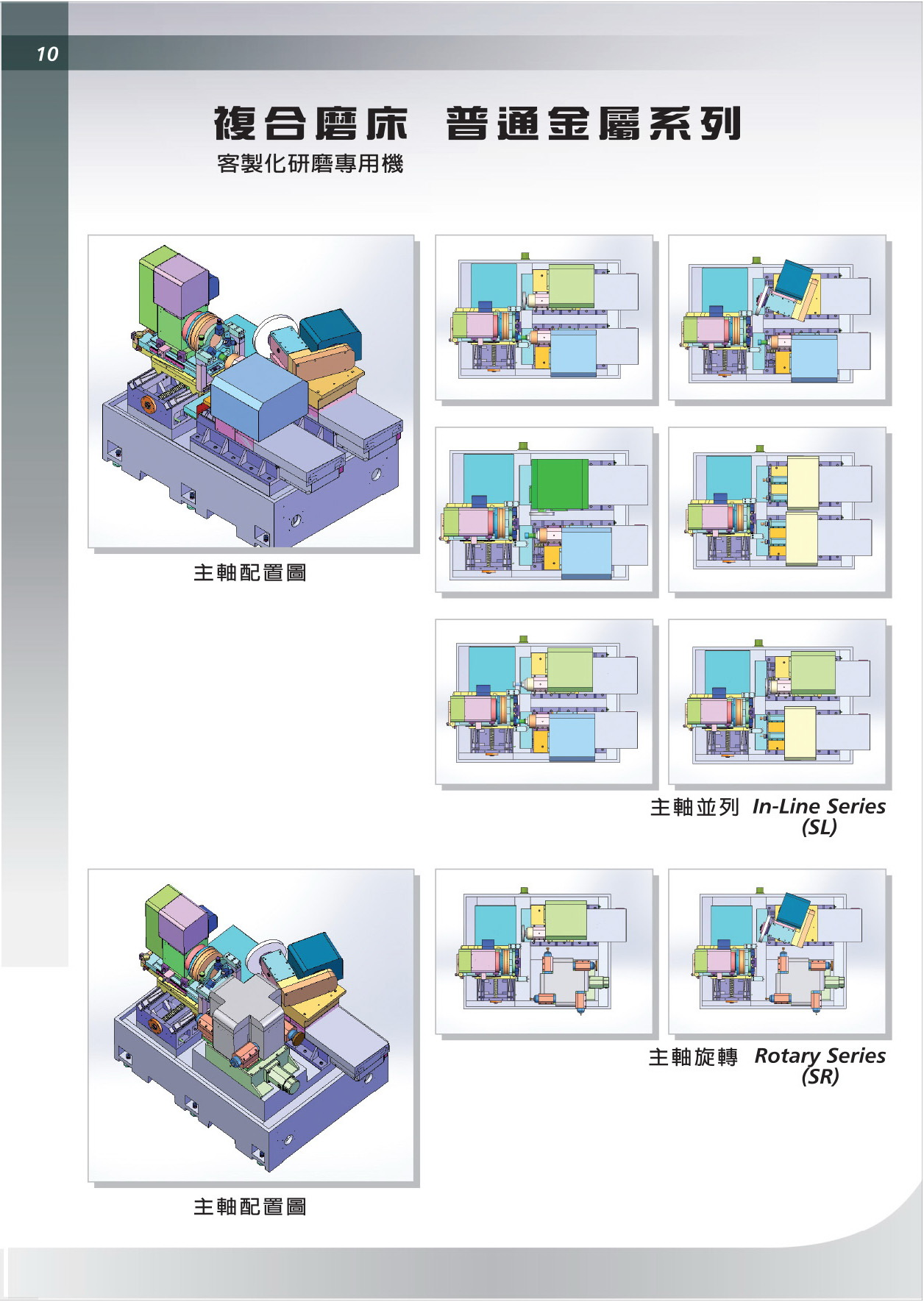

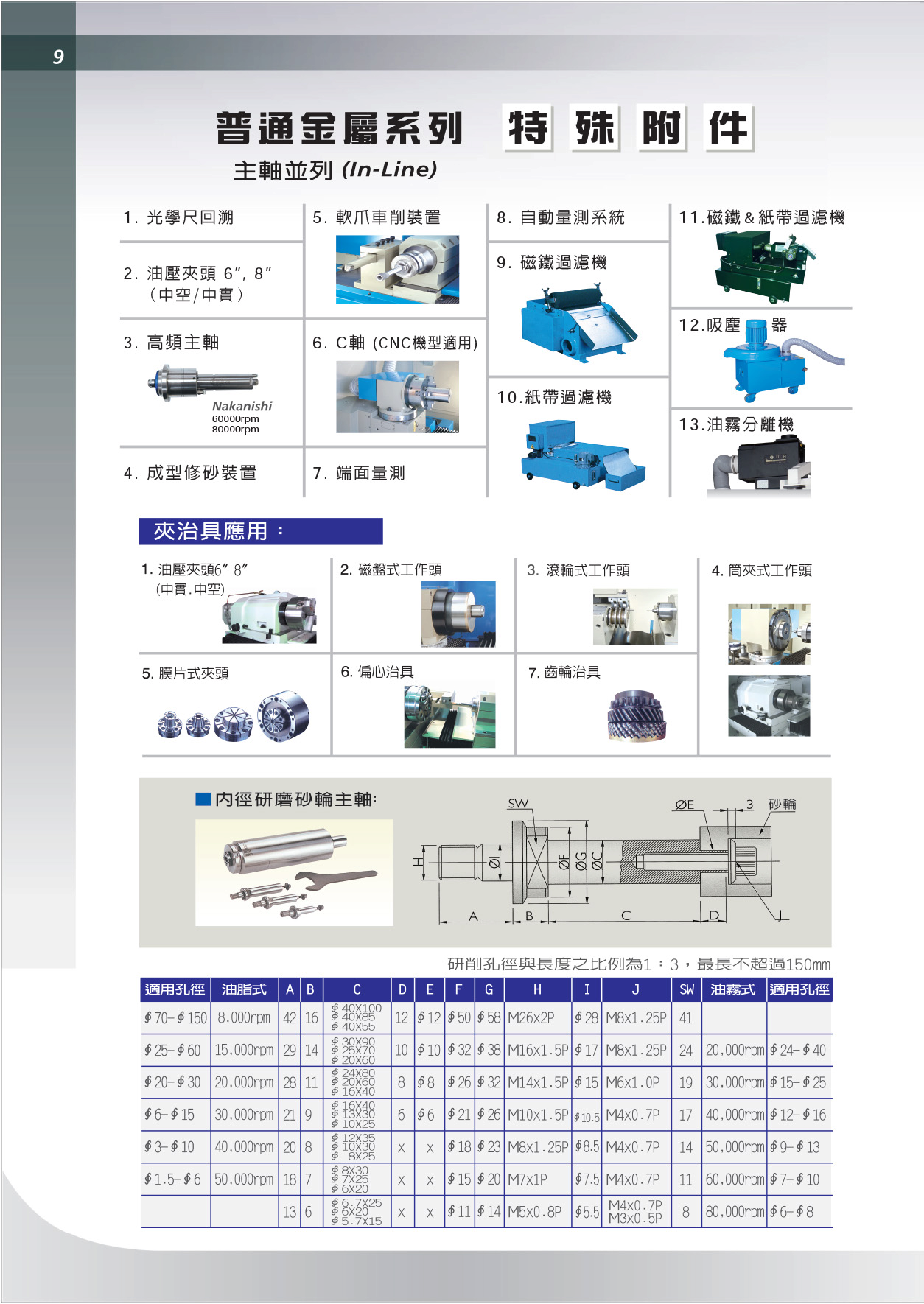

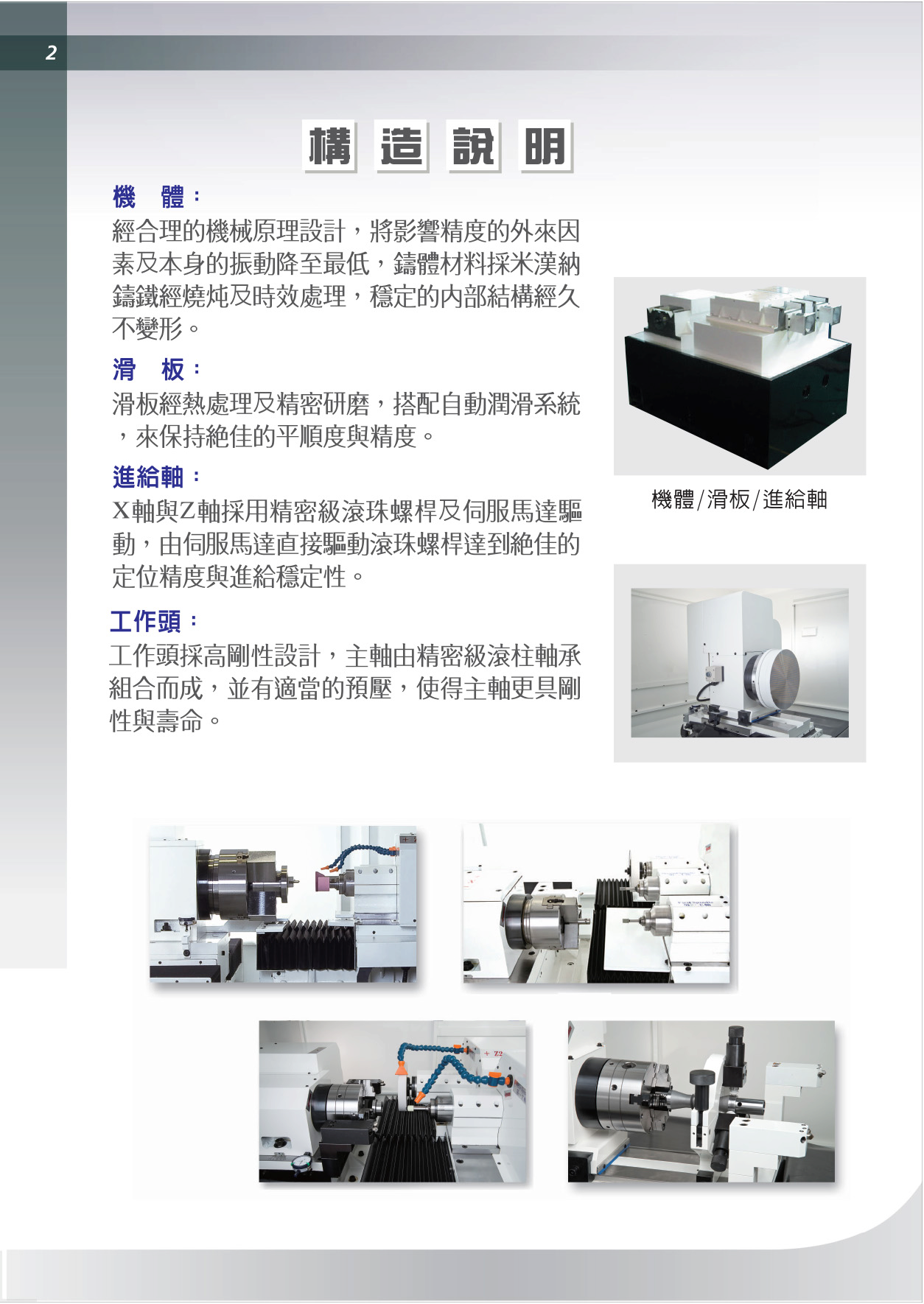

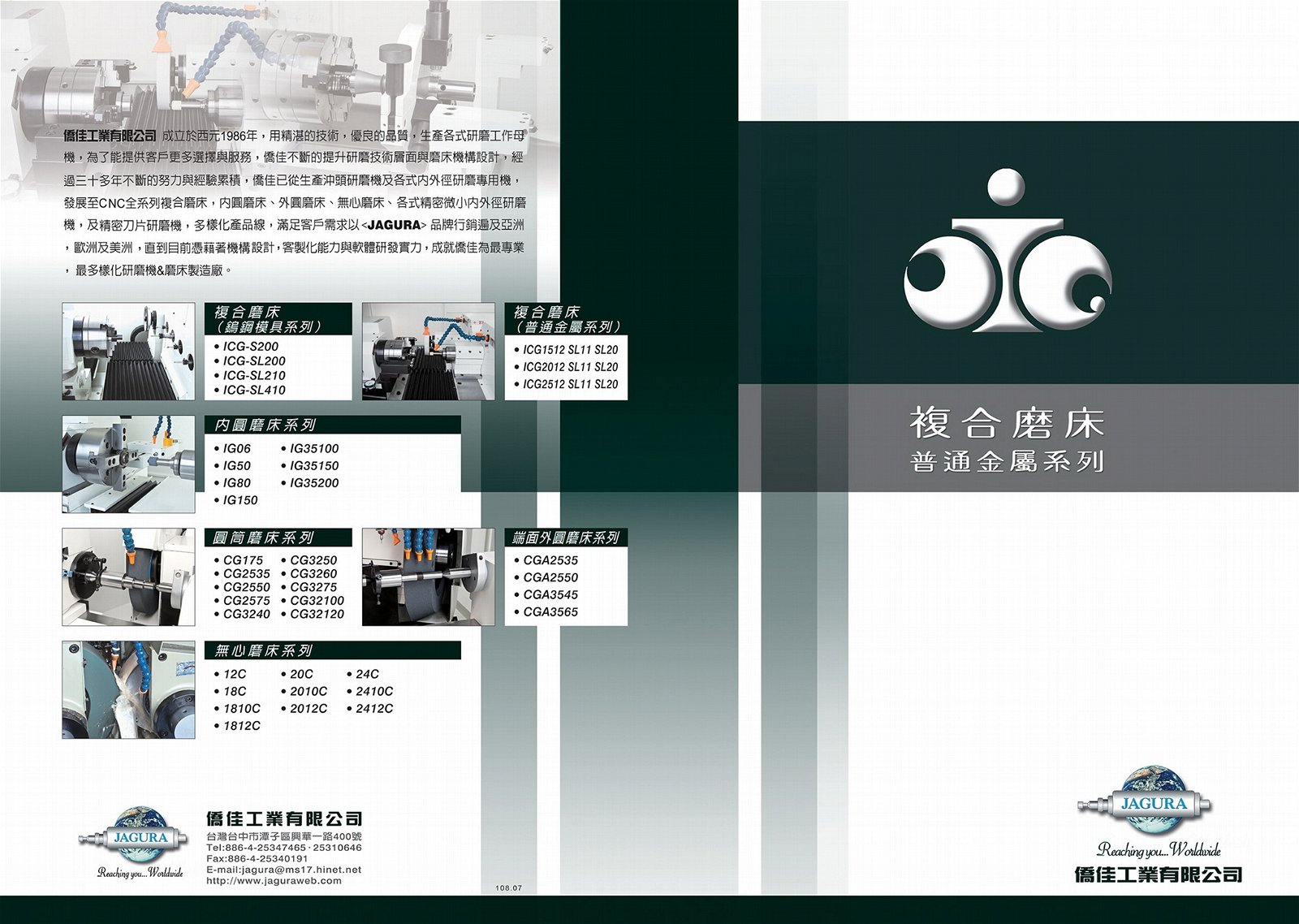

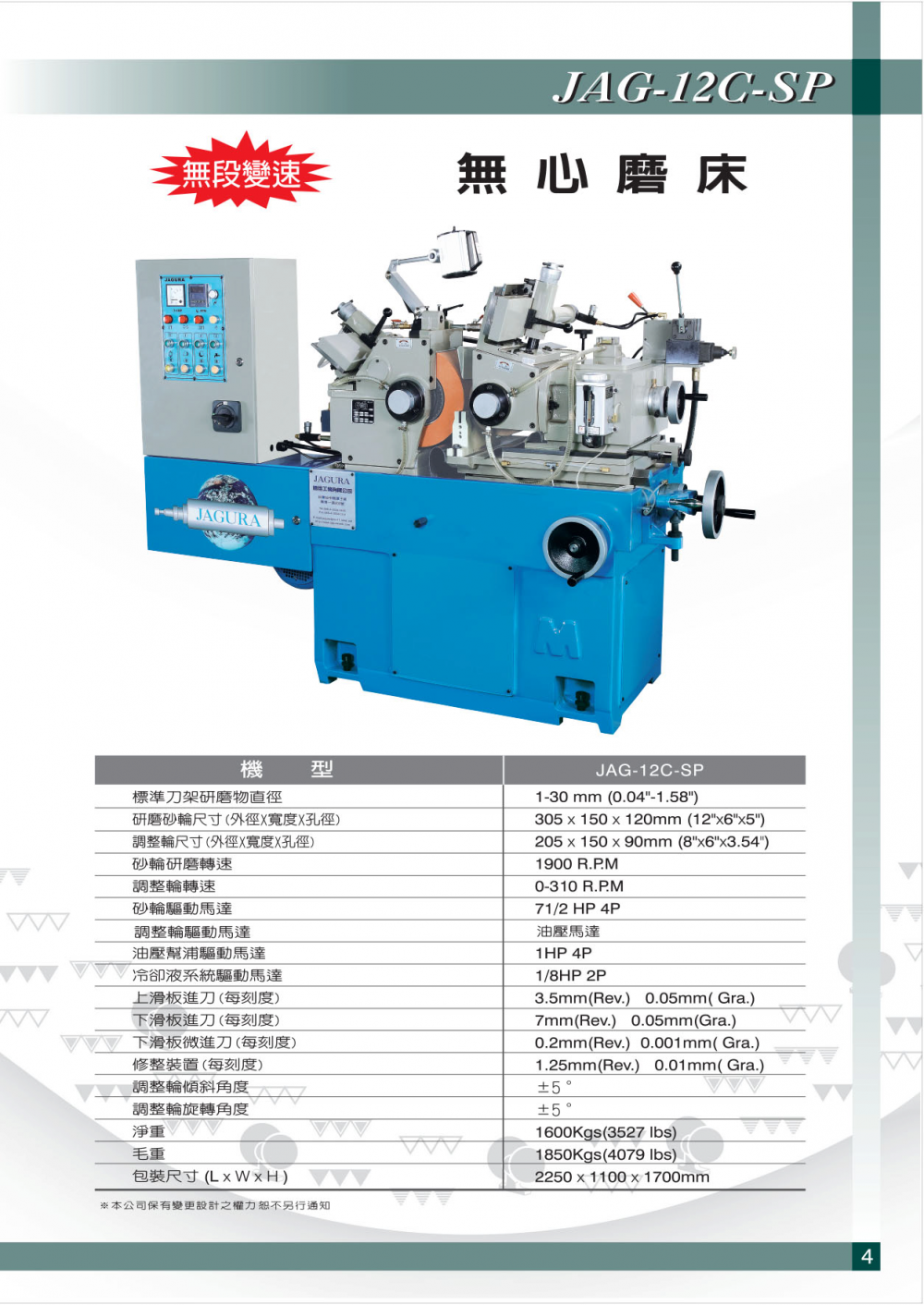

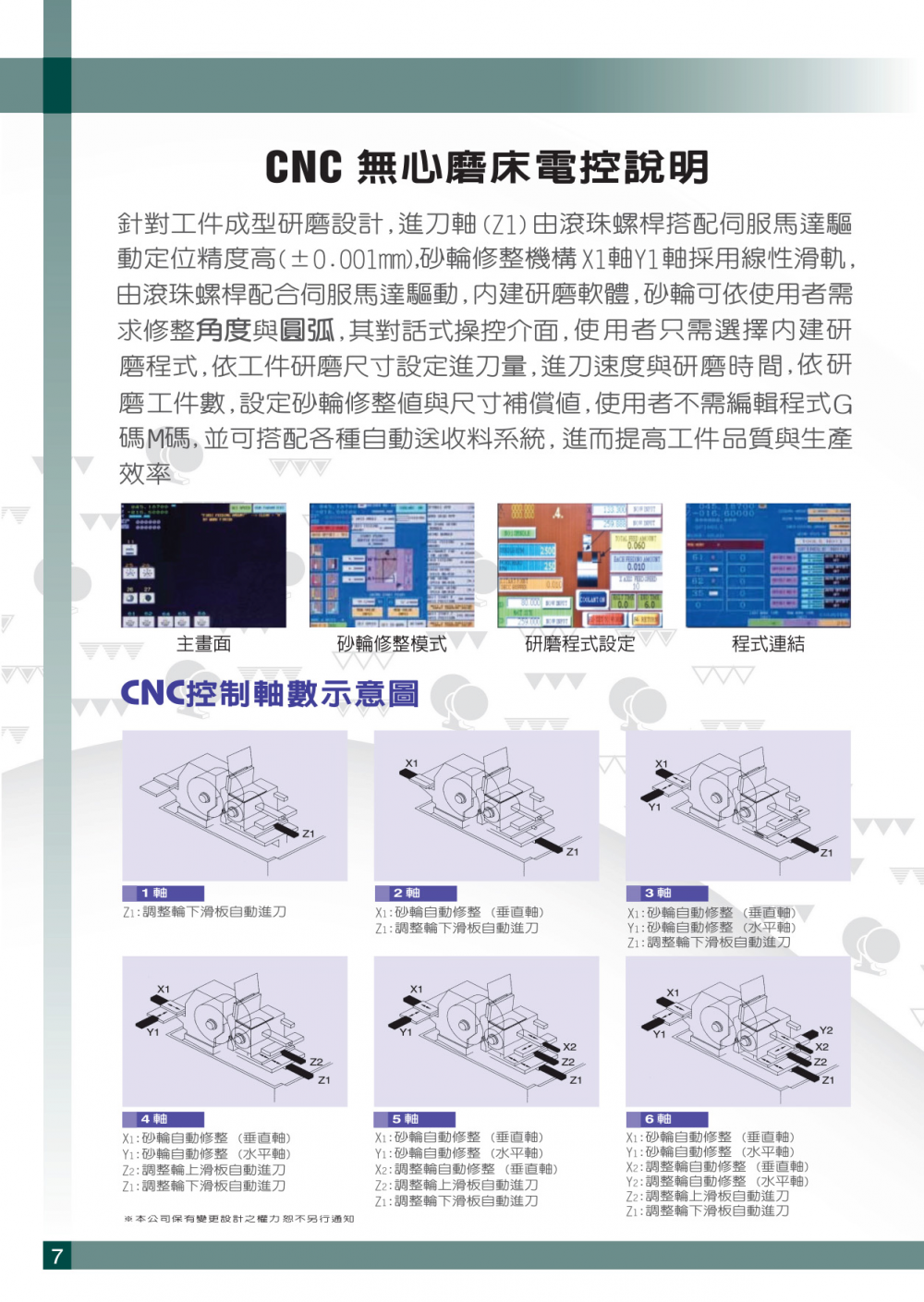

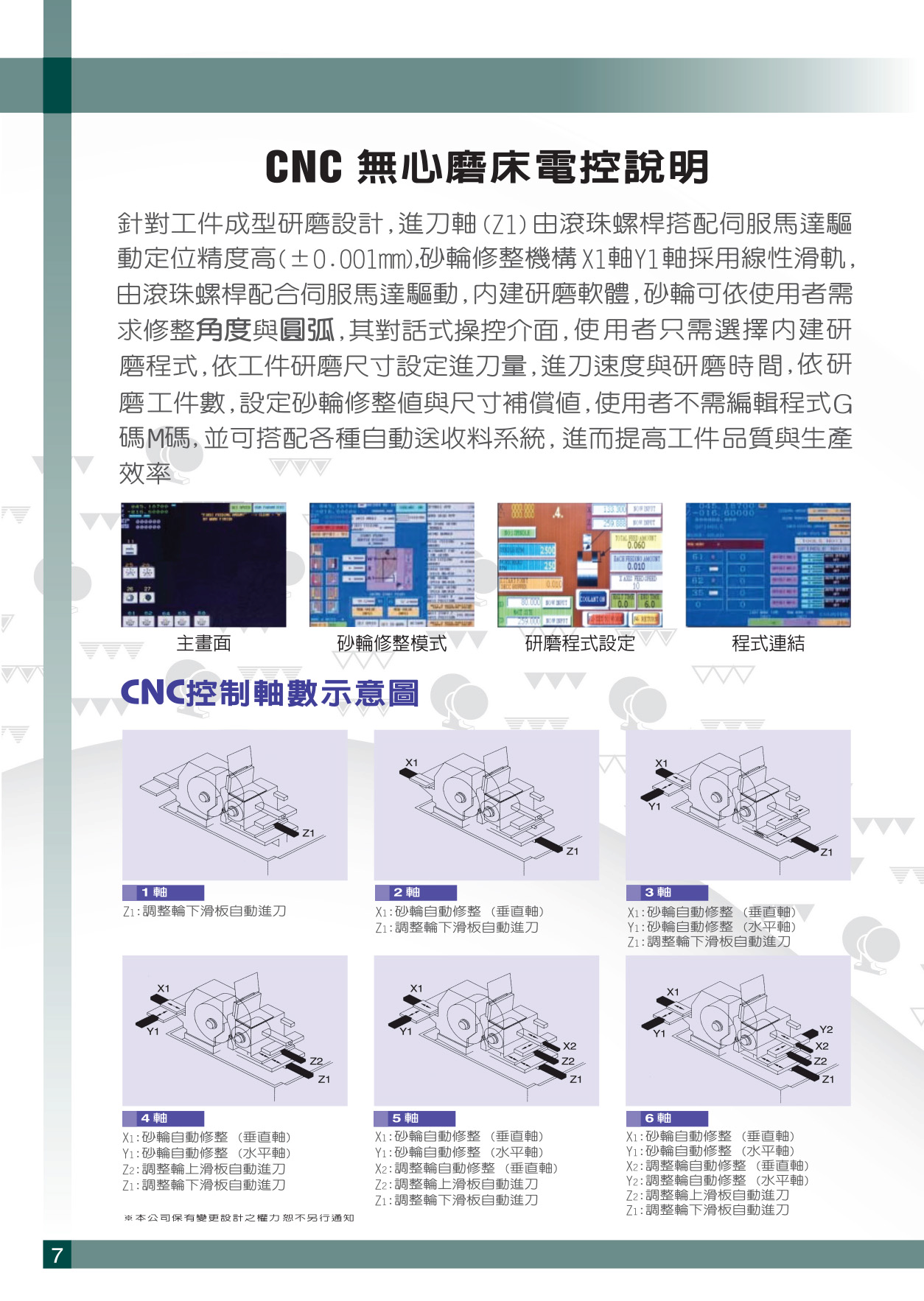

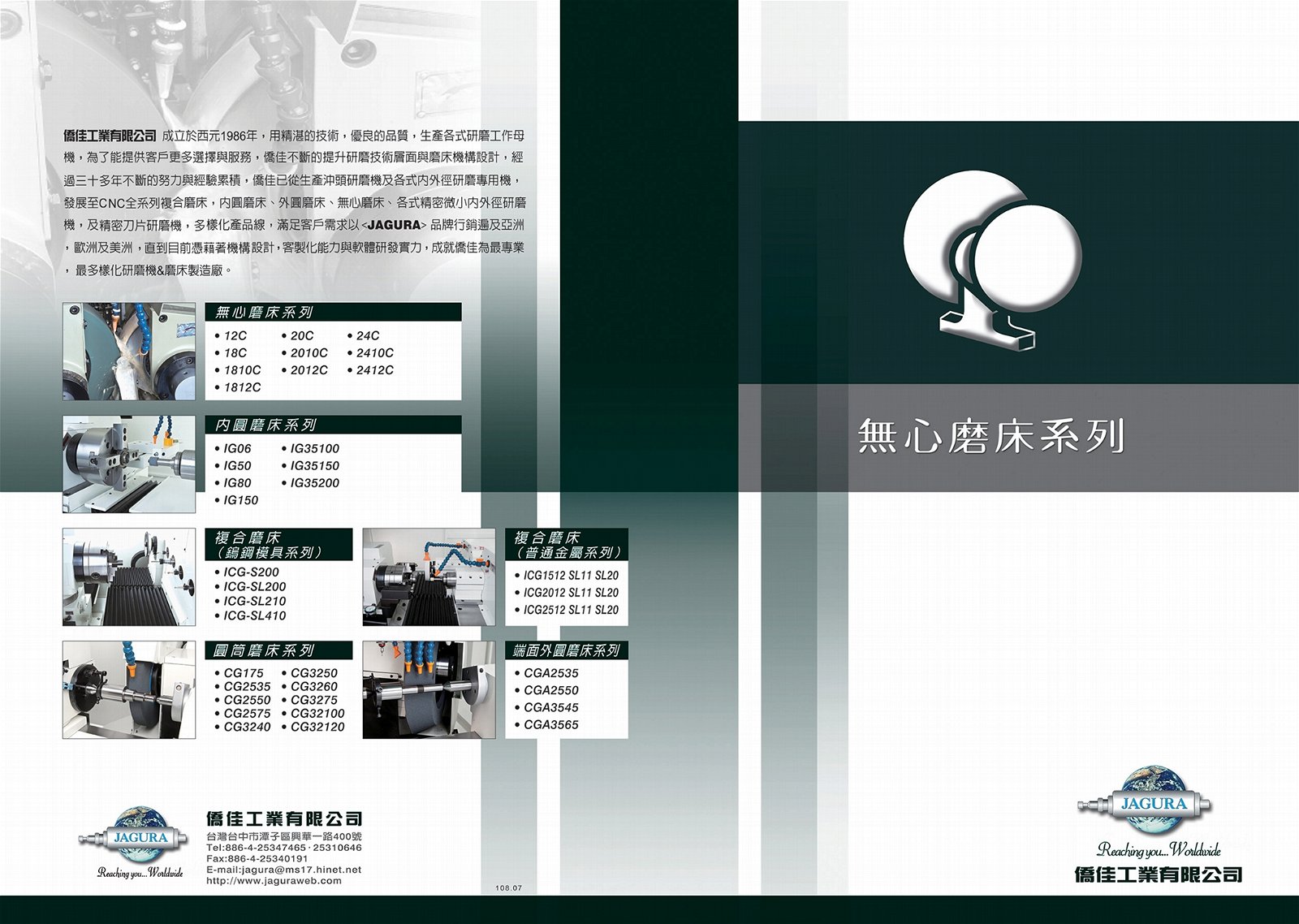

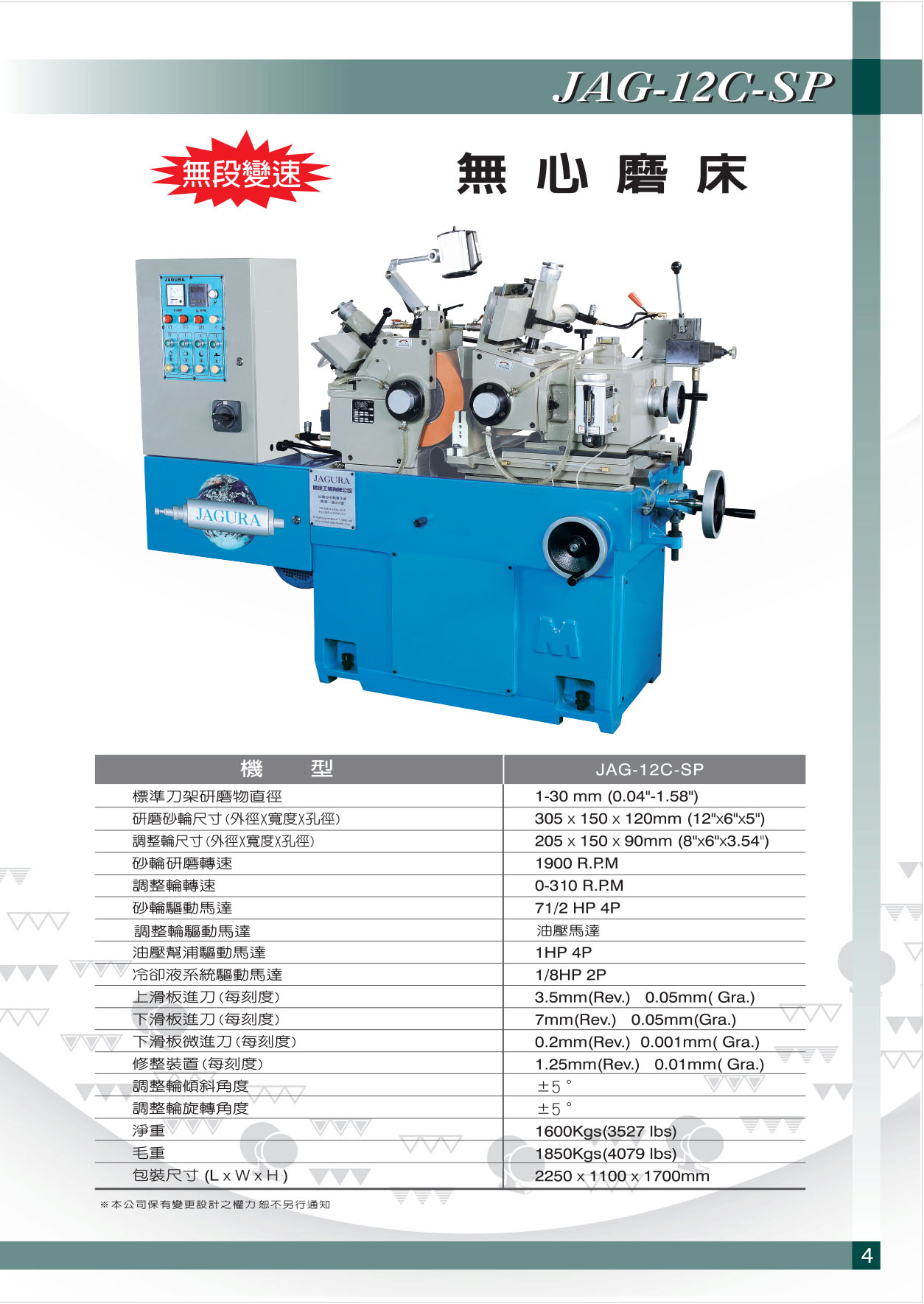

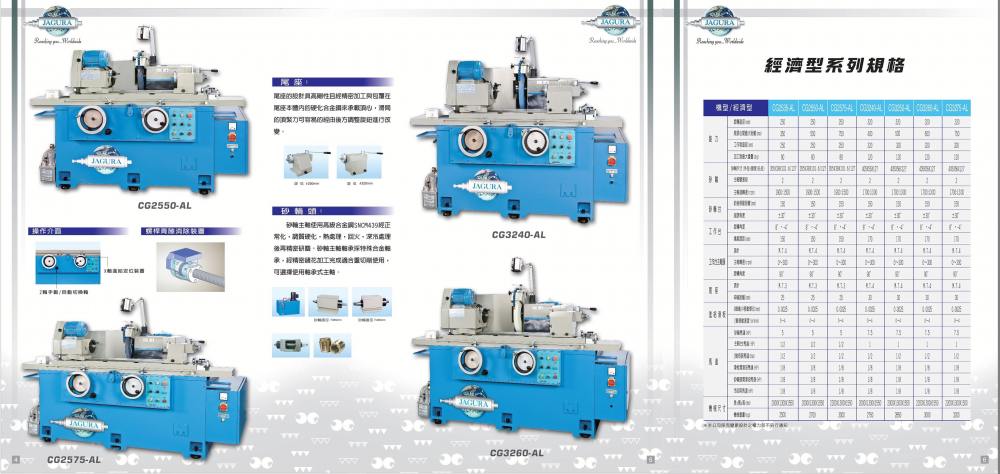

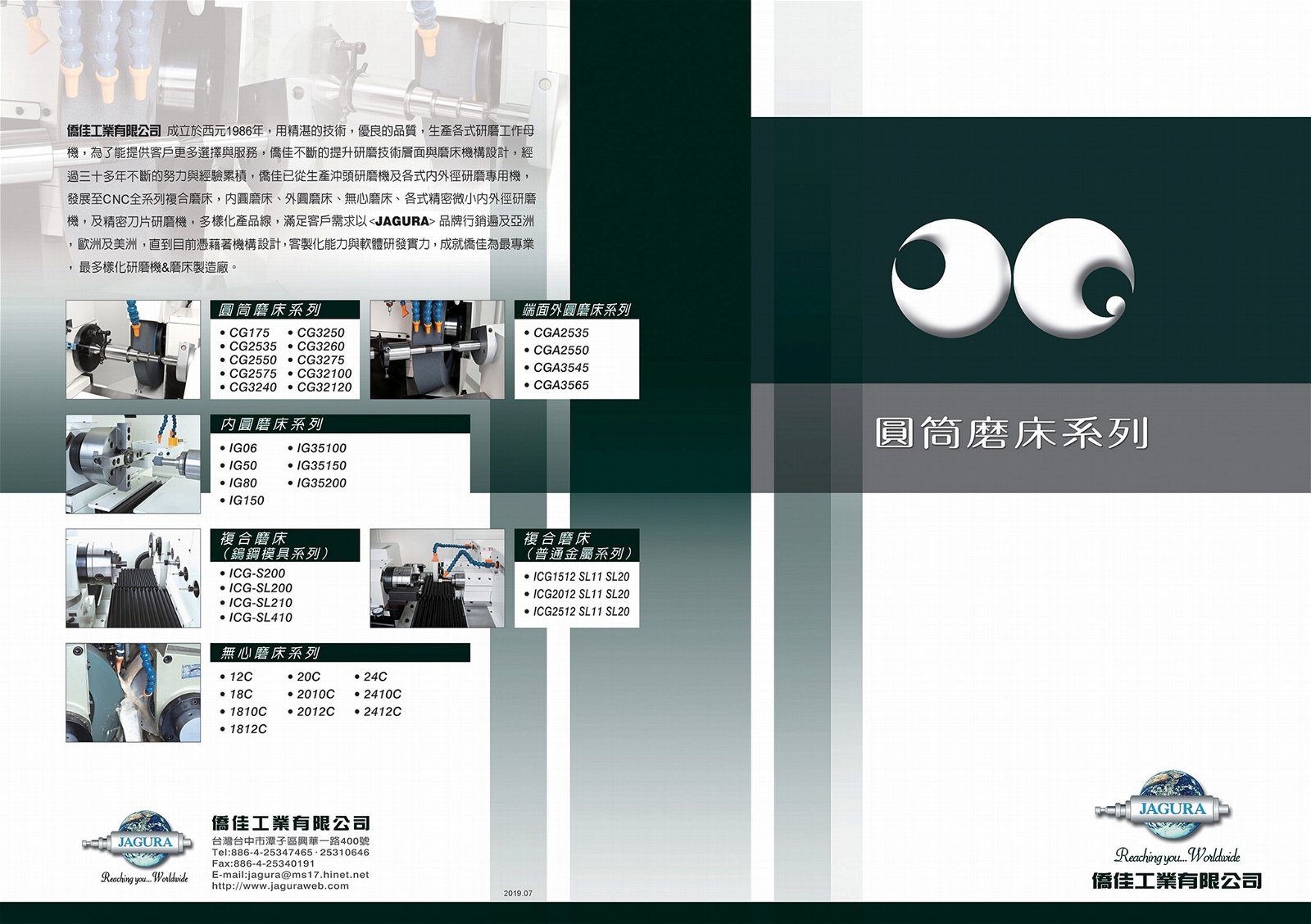

- AGURA PARAGON MACHINERY High Precision Compound, Internal Grinder, Centerless

- Japan Union-THS-10-Battery rupture disk Thickness measurement of pressure groove

- Japan RS-230 Ultrasonic Processing Machine

- PCV-30 High-efficiency machining center KIRA, Japan

- Ultra-small milling machining center for production line operation-PM150/PM250/P

- Model EZ230CNC+AEC+W-axis EZ-345CNC+AEC

- Japan Union-Thickness Measuring Microscope-THS-10-Explosion Disc for Lithium Bat

- Product Catalog

- News

- Contact Us

- Document