ATM-PNT-2112-012 SiC2 Crystal Trial Grinding Case - Outer Diameter Plane of Rod - Machining Test Report

1. At present, most of the third-generation semiconductor chips are single-crystal SICs. Those with higher transparency belong to processor chips, and those with higher carbon content and darker SICs belong to power component chips.

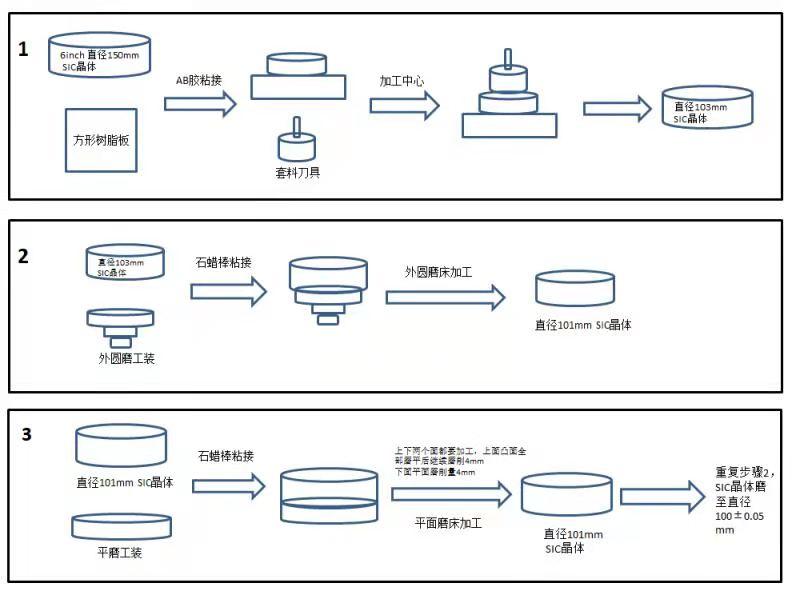

The outer diameter of the 4" wafer is about 6" (150mm), and the inner diameter of the diamond cutter is about 103mm. Therefore, 1-1.5mm of material collapse is still allowed, and about 1-1.5mm of both ends are leveled.

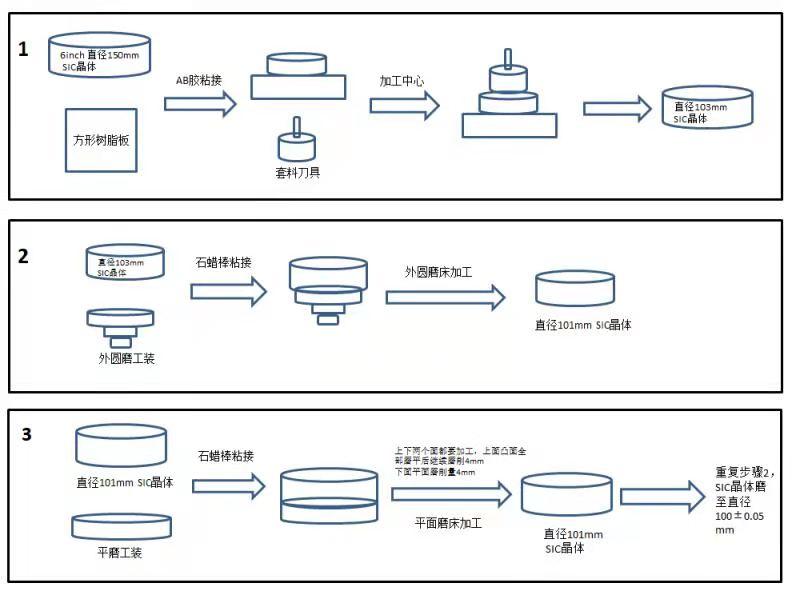

There is basically no chipping when grinding the outer diameter, only burrs. After the initial shaping of the ingot is completed, it is sliced. After the slicing is completed, each slice needs to be leveled, thinned, polished and cleaned.

Wafer is completed after repeated engineering.

2. The above processes are basically relatively mature in terms of 4", and they are gradually optimizing and improving the yield. The 6" part currently has a high defect rate and continues to improve! Of course, the 8" wafer is also continuing to optimize the process and improve the quality. Rate.

I think the third generation of semiconductors will still be dominated by 12” like SI wafers after many years, and even evolve to 16”-18”.

(The 6" crystal weight can only take out the 4" crystal rod, and the 8" crystal weight can only take out the 6" crystal rod)

3. The difficulty of processing lies in the fact that the tool is a diamond tool, and the hardness of the workpiece is close to that of diamond (the Mofit hardness is about 9.5), but the brittleness is higher than that of diamond. The main purpose of this test is to find the shape of the suitable diamond cutter,

Sintering method and other conditions. A test tool will waste tens of thousands of Taiwan dollars, but I hope it will be helpful for the promotion of FVGC.

The attached file provides you with a preliminary process drawing for easy understanding!

At present, the 4" process of single crystal SIC crystal growth is mature, and the thickness is less than 30mm. It is expected to be cut into 20-25 wafers. At present, SIC crystal growth continues to develop towards the thickness and diameter of 6" crystal mounds.

The cutting test report is based on the FVGC-50S trial processing (pulling out) 4” wafer, mainly grinding the outer circle. It is recommended to use a surface grinder for leveling the two ends, and the principle can be 6-8 per disk at a time, and the reverse side is leveled.

For leveling, if a rotary table grinder is used, although the processing efficiency is high, it can only grind one piece at a time, which is suitable for grinding 8” or more crystals or wafers.

In the test report, the spindle does not use ultrasonic spindle, because the hardness of single crystal SIC is similar to diamond, and its brittleness is higher! If ultrasonic is used, the effect will be better!