Sodick slow wire cutting ALN400G

Four-axis linear motor device

The four-axis axis adopts a high-performance linear motor independently developed and produced, which establishes a direct connection without a ball screw.

Drive method; backlash-free, correct shaft movement is maintained semi-permanently, which is traditional ball screw drive

way impossible. The characteristics of the linear motor are high response, high follow-up, control and

During machining, it exhibits excellent discharge characteristics.

new power unit

It integrates the tablet mode and the traditional mode, which is the first in the world, and makes the SPW of the CNC device further

upgrade. In addition, it is also equipped as standard with No-Bump Control II, Reduction II

Surface roughness during secondary machining, TMP control II for improving semi-finishing speed, etc.

Fully closed control

The world's four-axis HEIDENHAIN optical ruler (0.01um)

Automatic threading device

Realize high reliability automatic fusing and automatic wire threading (AWT)

Processing fluid temperature constant device

It can keep the temperature of the processing fluid stable and meet the requirements of high-precision cutting;

Processing liquid level automatic adjustment device

Through the automatic adjustment of the liquid level, unmanned operation can be realized (water spraying or water immersion can be used)

workbench

The original "C-shaped" workbench was changed to a ceramic "mouth-shaped" workbench;

UTY editing system

Through this system, operation program editing can be realized on the machine;

0.1 wire diameter cutting power supply

Equipped with a power supply that can be used for 0.1 wire diameter cutting to achieve smaller R angle processing;

TK2

The amount of deformation during processing is greatly reduced, depending on the application of the "TK2" feedback control circuit;

touch operation

ALN series wire cutting world is the first to be equipped with a touch panel computer operation mode;

Liquid level tracking function

Standard configuration Z-axis tracking liquid level tracking function, this solution can improve operability;

unmanned operation

Rely on high-speed automatic wiring device and liquid level tracking adjustment function to improve work efficiency;

self-developed

ALM series element technology is developed and manufactured by Sodick to exert its performance;

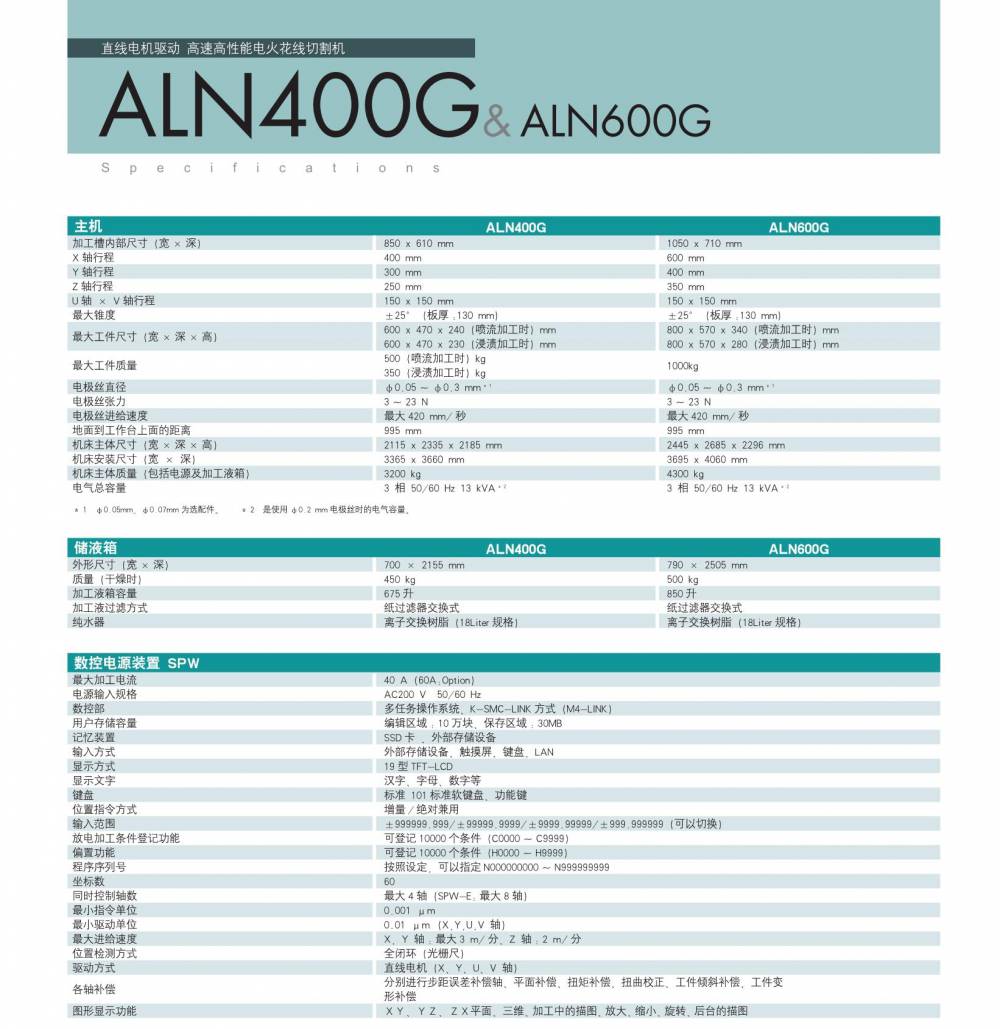

ALN400G

ALN400G Sodick slow-moving wire machine specifications (Sodick)

X, Y, Z stroke

400mm*300mm*250mm

U, V stroke

150mm*150mm

Taper machining control angle

±25° (plate thickness: 130mm)

Workpiece size (immersed in water)

600mm*470mm*240mm

Workpiece size (water spray)

600mm*470mm*230mm

Quality of processed material

500KG (water immersion), 350KG (water spray)

ALN400G electrode wire diameter

0.1mm - 0.3mm

Distance from ground to work surface

995mm

Main body size of ALN400G machine

2115mm*2335mm*2185mm

total input power

11kw, 5060 Hz

ALN400G total weight

3350KG

ALN400G

ALN400G Sodick Wire Cutting Power Supply Unit Instructions (Sodick)

Machining current

40A (optional 60A)

power input

380V (system power 220V)

CNC device

Multitasking operating system, K - SMC - LINK mode (M 4 - LINK)

memory device

SSD, external storage

Input

External memory, multi-touch screen, on-screen keyboard, local area network

Display method

Type 19 TFT

display text

Chinese characters (JIS), letters, numbers, etc.

keyboard

Standard 101 reference keyboard, function keys

position command method

Incremental coordinates, coordinates

EDM condition registration function

10000 conditions can be registered (C000-C9999)

Compensation function

10000 conditions can be registered (H000-H9999)

Program sequence number specification

Setting ratio N 000000000-N 999999999 possible

number of coordinates

60

Simultaneous control of the number of axes

4 axes (SPW - E: 8 axes)

Minimum instruction unit

0.001um

Minimum drive unit

0.01um (X, Y, U, V) axis

Transmission speed

X, Y axis 3m/min; Z axis 2m/min

position detection system

Fully closed loop control (optical ruler)

Drive System

Linear motor (X, Y, U, V axis)

various compensation

Each axis step gauge error compensation, clearance compensation, torque compensation

Graphics function

Plane, drawing during processing, 3D, enlargement, reduction, rotation, background drawing

ALN400G

ALN400G Sodick Wire Cutting Inclusion Instructions (Sodick)

The ambient temperature will affect the accuracy of the machine tool, a constant temperature working environment is very necessary (installation of air conditioners)

)

The impact of vibration on electrical processing is fatal, and the work site needs to be far away from the source of the earthquake or take measures such as anti-vibration trenches;

Water, electricity and gas are indispensable; pure water, power supply with voltage regulation, and gas source for oil-water separation;

It is recommended to prepare some commonly used consumables, such as electrode wires, conductive blocks, filters, resins, water caps, etc.;

Sodick ALN400Q Sodick slow wire cutting

X, Y, Z stroke

400mm*300mm*250mm

U, V stroke

150mm*150mm

Internal dimension of machining groove

850mm*745mm

Taper machining control angle

±25° (plate thickness: 130mm)

Workpiece size (water spray)

600mm*470mm*240mm

Workpiece size (immersed in water)

600mm*470mm*230mm

Quality of processed material

500KG (water immersion), 350KG (water spray)

electrode wire diameter

0.1mm - 0.3mm

Electrode wire feed speed

420mmsec

ALN400Q machine body size

2115mm*2335mm*2185mm

ALN400Q installation dimensions

3365mm*3660mm

ALN400Q total weight

3100KG

Sodick wire cutting power supply unit Sodick ALN400Q (SPW)

Machining current

40A (optional 60A)

power input

380V (system power 220V)

CNC device

Multitasking operating system, K - SMC - LINK mode (M 4 - LINK)

memory device

SSD, external storage

Input

External memory, multi-touch screen, on-screen keyboard, local area network

Display method

Type 19 TFT

display text

Chinese characters (JIS), letters, numbers, etc.

keyboard

Standard 101 reference keyboard, function keys

position command method

Incremental coordinates, coordinates

EDM condition registration function

10000 conditions can be registered (C000-C9999)

Compensation function

10000 conditions can be registered (H000-H9999)

Program sequence number specification

Setting ratio N 000000000-N 999999999 possible

number of coordinates

60

Simultaneous control of the number of axes

4 axes (SPW - E: 8 axes)

Minimum instruction unit

0.001um

Minimum drive unit

0.01um (X, Y, U, V) axis

Transmission speed

X, Y axis 3m/min; Z axis 2m/min

position detection system

Fully closed loop control (optical ruler)

Drive System

Linear motor (X, Y, U, V axis)

various compensation

Each axis step gauge error compensation, clearance compensation, torque compensation

Graphics function

Plane, drawing during processing, 3D, enlargement, reduction, rotation, background drawing

Sodick jogging silk

Sodick Wire Cutting Inclusion Instructions Sodick ALN400Q (Intelligent Wire Cutting Machine)

The ambient temperature will affect the accuracy of the machine tool, a constant temperature working environment is very necessary (installation of air conditioners)

)

The impact of vibration on electrical processing is fatal, and the work site needs to be far away from the source of the earthquake or take measures such as anti-vibration trenches;

Water, electricity and gas are indispensable; pure water, power supply with voltage regulation, and gas source for oil-water separation;

It is recommended to prepare some commonly used consumables, such as electrode wires, conductive blocks, filters, resins, water caps, etc.;