|

|

|

|

AGURA PARAGON MACHINERY High Precision Compound, Internal Grinder, Centerless

| |

|

PARAGON MACHINERY External Grinding Machines

|

- External Grinding Machines

- The GU Series are compact universal cylindrical grinding machines by PARAGON. They are suitable for long, multi-steps, and profile cylindrical grinding. Along with the optional internal grinding unit attachment, they provide more flexibility and offer the best choice for your needs. The main features are as follow:

- Grinding wheelhead spindle with unique Hydrostatic Bearings

- Multi-function, high roundness Workhead

- Hydraulic and manual adjustable Tailstock

- High rigid Machine Base with Hydrostatic Lubrication on guideways

- Heidenhain sub-μm Linear Scale with closeloop feedback.

SuperB B-axis Series

- The rotary motor in the grinding spindle base adopts DD motor for driect drive, achieving no backlash, high speed and high precision rapid rotary positioning.

- Feed guideway for the grinding wheel base uses optimized rectangular design with the concept of full enclosure to allow highly rigid and precise machining performance.

- Grinding wheel drive motor utilizes highly efficient and high torque motor to demonstrate heavy-duty cutting ability and highly efficient grinding capability.

- Choose the best combination of grinding wheel package to enable compound grinding and multiple machining procedures with just one clamping, showing high speed, high precision and high efficiency capabilities.

| |

|

| SuperB GU-35100CNC |

| Swing over table(mm) |

Ø350 |

| Distance between centers(mm) |

1,000 |

| Max. outer grinding wheel dimension(mm) |

Ø510 / Ø510 |

| |

| Machine Dimension

(WxDXH mm) |

4,200 x 2,000 x 2,260 |

| Machine Weight (kg) |

7,600 |

|

|

Ultra Polygon Series

- New design for eccentric or non-round parts grinding

- Applications include eccentric, polygon, camshaft and crankshaft parts grinding etc.

| |

Ultra GU-3550CNC |

| Swing over table(mm) |

Ø350 |

| Distance between centers(mm) |

500 |

| Max. outer grinding wheel dimension(mm) |

Ø405 |

| |

| Machine Dimension

(WxDXH mm) |

3,200 x 2,000 x 2,260 |

| Machine Weight (kg) |

4,100 |

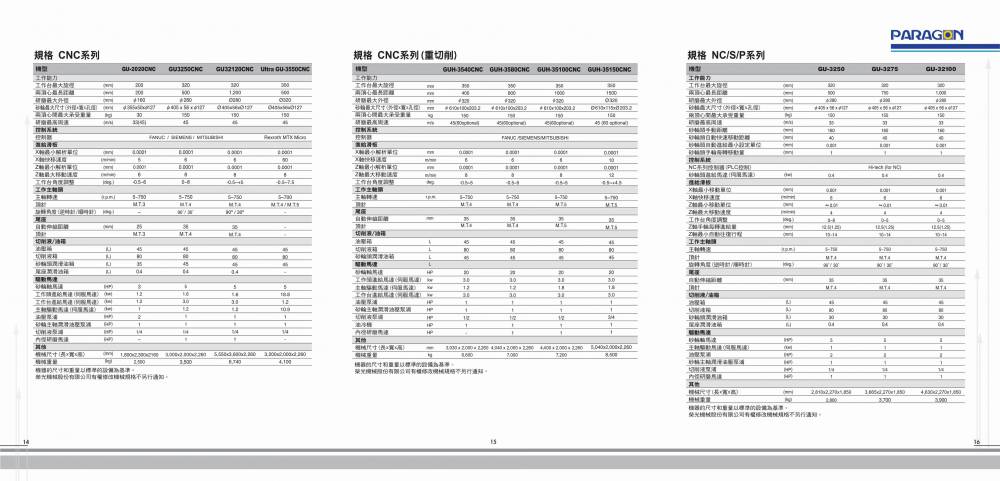

CNC Series

- Equipped with FANUC color screen and the latest technology in digital control systems.

- X/Z axes have high torque Servo Motor directly coupled to the class C1 Ballscrew (Ø40mm)

| |

GU-2020CNC |

GU-3250CNC |

GU-32120CNC |

| Swing over table(mm) |

Ø200 |

Ø320 |

Ø320 |

| Distance between centers(mm) |

200 |

500 |

1,200 |

| Max. outer grinding wheel dimension(mm) |

Ø355 |

Ø405 |

Ø405 |

| Machine Dimension

(WxDXH mm) |

1,800 x 2,300 x 2,160 |

3,000 x 2,000 x 2,260 |

5,550 x 3,600 x 2,260 |

| Machine Weight (kg) |

2,500 |

3,500 |

6,740 |

CNC Series (Heavy Duty)

- The new generation CNC universal cylindrical grinding machine (Heavy-Duty) GUH CNC Series by PARAGON is especially designed for high-speed grinding, offering greater capabilities than the GU CNC Series. This innovative designed machine with optimal and sturdy components can provide long service life and less down time, will bring you a new grinding experience.

- X-axis and Z-axis greater span of guideways afford larger load capacity than GU CNC Series.

- Time-saving and high efficiency in cycle and setup. The machine can accommodate an extra large grinding wheel with 610 mm diameter and 115 mm width which can complete multi-steps machining at one time, greatly shortening operation time and assuring high rigidity and precision.

- Rigid and precise hydrostatic-hydrodynamic hybrid bearings on angular wheelhead.

| |

GUH-3540CNC |

GUH-3580CNC |

GUH-35100CNC |

GUH-35150CNC |

| Swing over table(mm)) |

Ø350 |

Ø350 |

Ø350 |

Ø350 |

| |

|

| |

|

| |

Product Image

无心磨床系列介绍

创新先进的调轮主轴不需要法兰,并结合斜角滚珠轴承和滚柱轴承,能维持主轴超高精度旋转和高刚性。

| RC-12B |

RC-16B |

RC-18B |

RC-1812B |

RC-20B |

|

| 研磨范围(直径mm) |

Ø1-Ø30 |

Ø2-Ø40 |

Ø2-Ø50 |

Ø2-Ø50 |

Ø2-Ø50 |

| 砂轮尺寸(直径mm) |

Ø305 x 150 x Ø120 |

Ø405 x 205 x Ø203.2 |

Ø455 x 205 x Ø228.6 |

Ø455 x 305 x Ø228.6 |

Ø510 x 205 x Ø304.8 |

| 机械尺寸

(长x宽x高mm) |

1,900×1,550×1,420 |

1,900×1,550×1,420 |

2,450×2,050×1,600 |

2,450×2,100×1,600 |

2,650×2,150×1,600 |

| 机械重量(kg) |

1,500 |

2,400 |

3,200 |

3,700 |

4,000 |

液动承伺服系列(S系列)

| RC-12S |

RC-18S |

|

| 研磨范围(直径mm) |

Ø1-Ø30 |

Ø2-Ø50 |

| 砂轮尺寸(直径mm) |

Ø305 x 150 x Ø120 |

Ø455 x 205 x Ø228.6 |

| 机械尺寸

(长x宽x高mm) |

1,900×1,550×1,420 |

2,300 x 1,800 x 1,600 |

| 机械重量 (kg) |

1,700 |

3,300 |

液静承系列 (H系列)

由高压油膜所覆盖,能消除金属与金属间的摩擦、过热和漏油等问题,减少动力耗损,提高刚性和减震性能。

| RC-18H |

RC-20H |

|

| 研磨范围(直径mm) |

Ø2-Ø50 |

Ø2-Ø50 |

| 砂轮尺寸(直径mm) |

Ø455 x 205 x Ø228.6 |

Ø510 x 205 x Ø304.8 |

| 机械尺寸

(长x宽x高mm) |

2,300 x 2,100 x 1,600 |

2,300 x 1,800 x 1,600 |

| 机械重量 (kg) |

3,500 |

3,900 |

CNC系列

| RC-12CNC |

RC-18CNC |

RC-1812CNC |

RC-20CNC |

|

| 研磨范围(直径mm) |

Ø1-Ø30 |

Ø2-Ø50 |

Ø2-Ø50 |

Ø2-Ø50 |

| 砂轮尺寸(直径mm) |

Ø305 x 150 x Ø120 |

Ø455 x 205 x Ø228.6 |

Ø455 x 305 x Ø228.6 |

Ø510 x 205 x Ø304.8 |

| 机械尺寸

(长x宽x高mm) |

3,432 x 2,870 x 1,997 |

3,880 x 3,265 x 2,040 |

3,200 x 2,830 x 1,730 |

3,250 x 3,010 x 1,730 |

| 机械重量 (kg) |

2,100 |

4,200 |

4,500 |

4,800 |

NC系列

-

调轮搭配滚动轴承。

-

在进行加工时,调轮可迅速接近工件进行加工

-

砂轮可选配动压或液静承

-

2-3轴可进行砂轮修砂与调轮进给补偿

-

MITSUBISHI PLC 的控制器和伺服马达

| RC-12NC |

RC-18NC |

RC-1812NC |

RC-20NC |

|

| 研磨范围(直径mm) |

Ø1-Ø30 |

Ø2-Ø50 |

Ø2-Ø50 |

Ø2-Ø50 |

| 砂轮尺寸(直径mm) |

Ø305 x 150 x Ø120 |

Ø455 x 205 x Ø228.6 |

Ø455 x 305 x Ø228.6 |

Ø510 x 205 x Ø304.8 |

| 机械尺寸

(长x宽x高mm) |

3,432 x 2,870 x 1,997 |

3,880 x 3,265 x 2,040 |

3,200 x 2,830 x 1,730 |

3,250 x 3,010 x 1,730 |

| 机械重量 (kg) |

2,100 |

4,200 |

4,500 |

4,800 |

经济型系列

皆使用高级超合金钢,经过一道道制程处理,搭配润滑油,其手工铲花能维持研磨主轴高精度旋转和刚性,承受最小间距重切削研磨。

| RC-12 |

RC-18 |

RC-1812 |

RC-20 |

|

| 研磨范围(直径mm) |

Ø1-Ø30 |

Ø2-Ø50 |

Ø2-Ø50 |

Ø2-Ø50 |

| 砂轮尺寸(直径mm) |

Ø305 x 150 x Ø120 |

Ø455 x 205 x Ø228.6 |

Ø455 x 305 x Ø228.6 |

Ø510 x 205 x Ø304.8 |

| 机械尺寸

(长x宽x高mm) |

1.900 x 1,550 x 1,420 |

2,300 x 1,800 x 1,600 |

2,300 x 2,100 x 1,600 |

2,500 x 2,150 x 1,600 |

| 机械重量 (kg) |

1,700 |

3,300 |

3,500 |

3,900 |

PARAGON MACHINERY External GrindinGU-2020CNC-3250CNC-32120CNC

Product Image

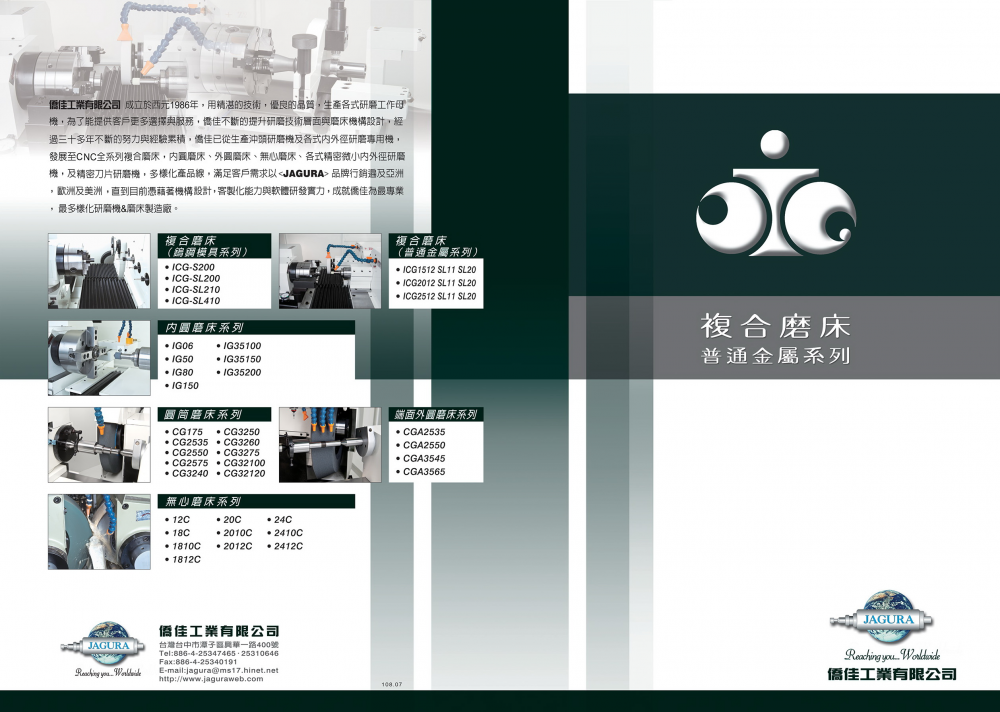

JAGURA internal and external cylindrical grinder JAG-ICG2512, 2012, 1512

|

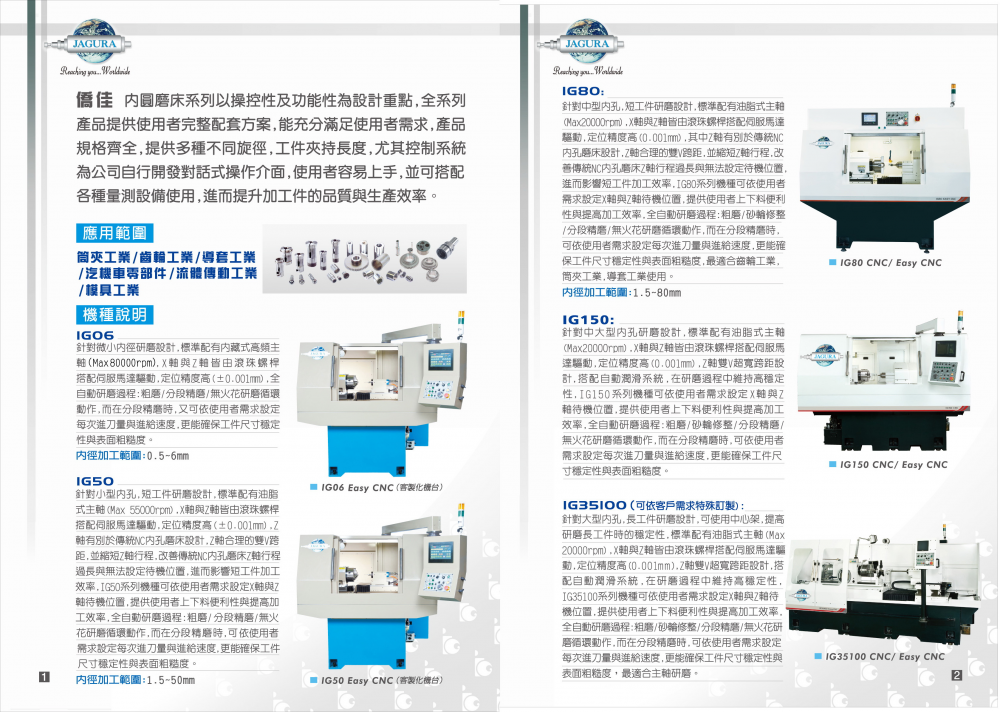

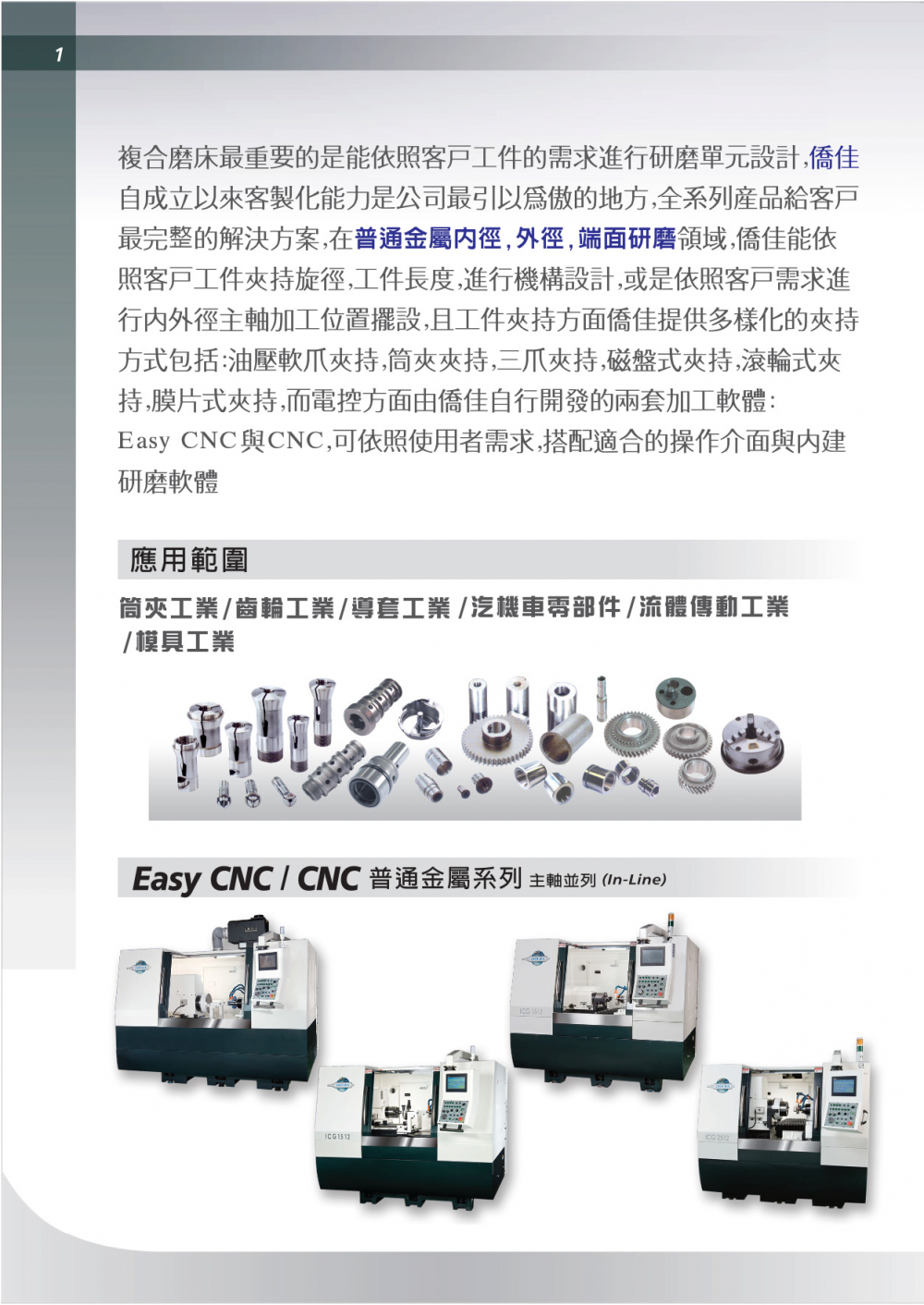

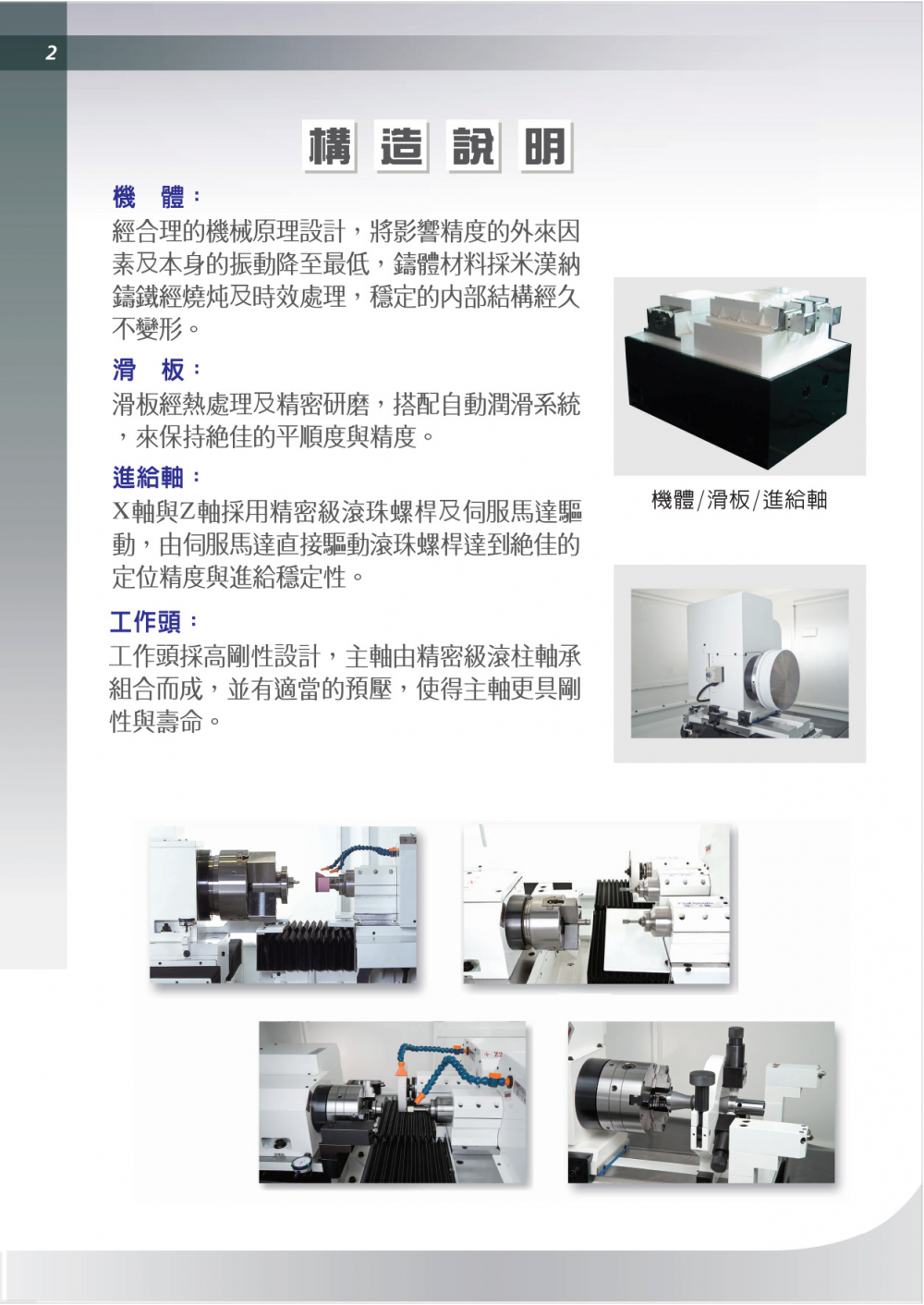

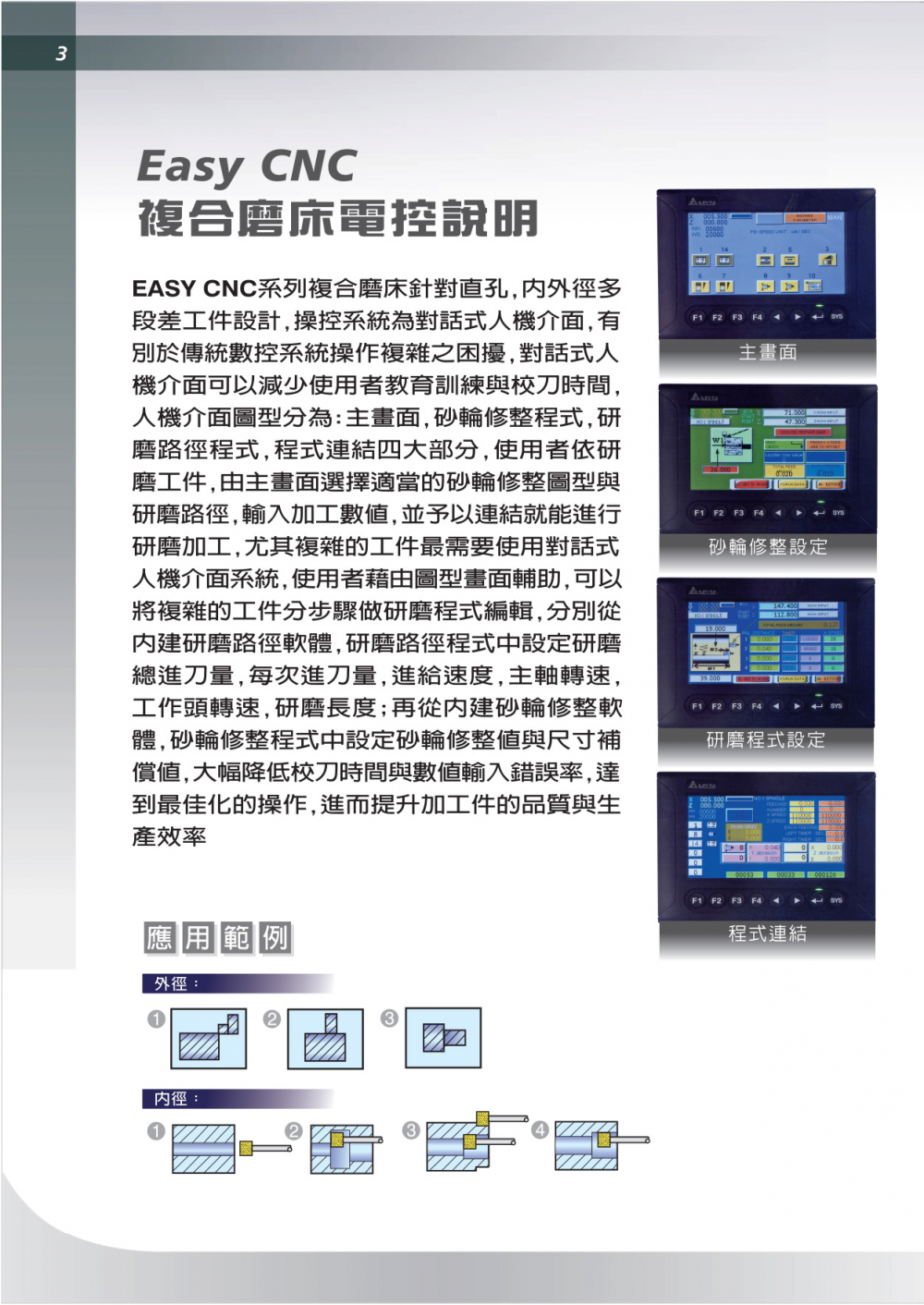

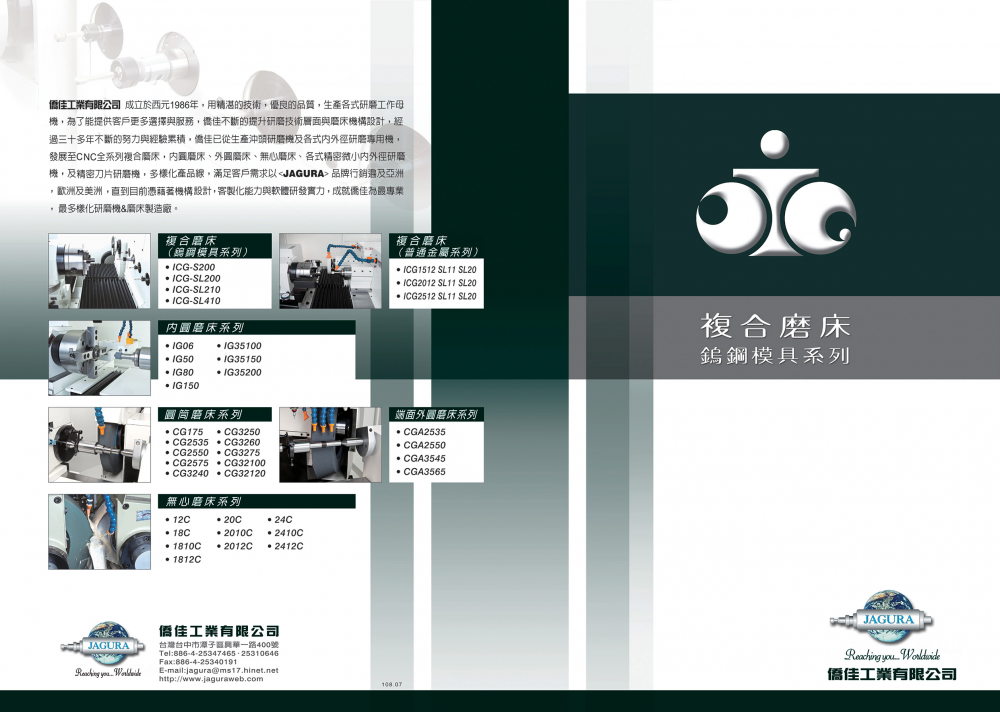

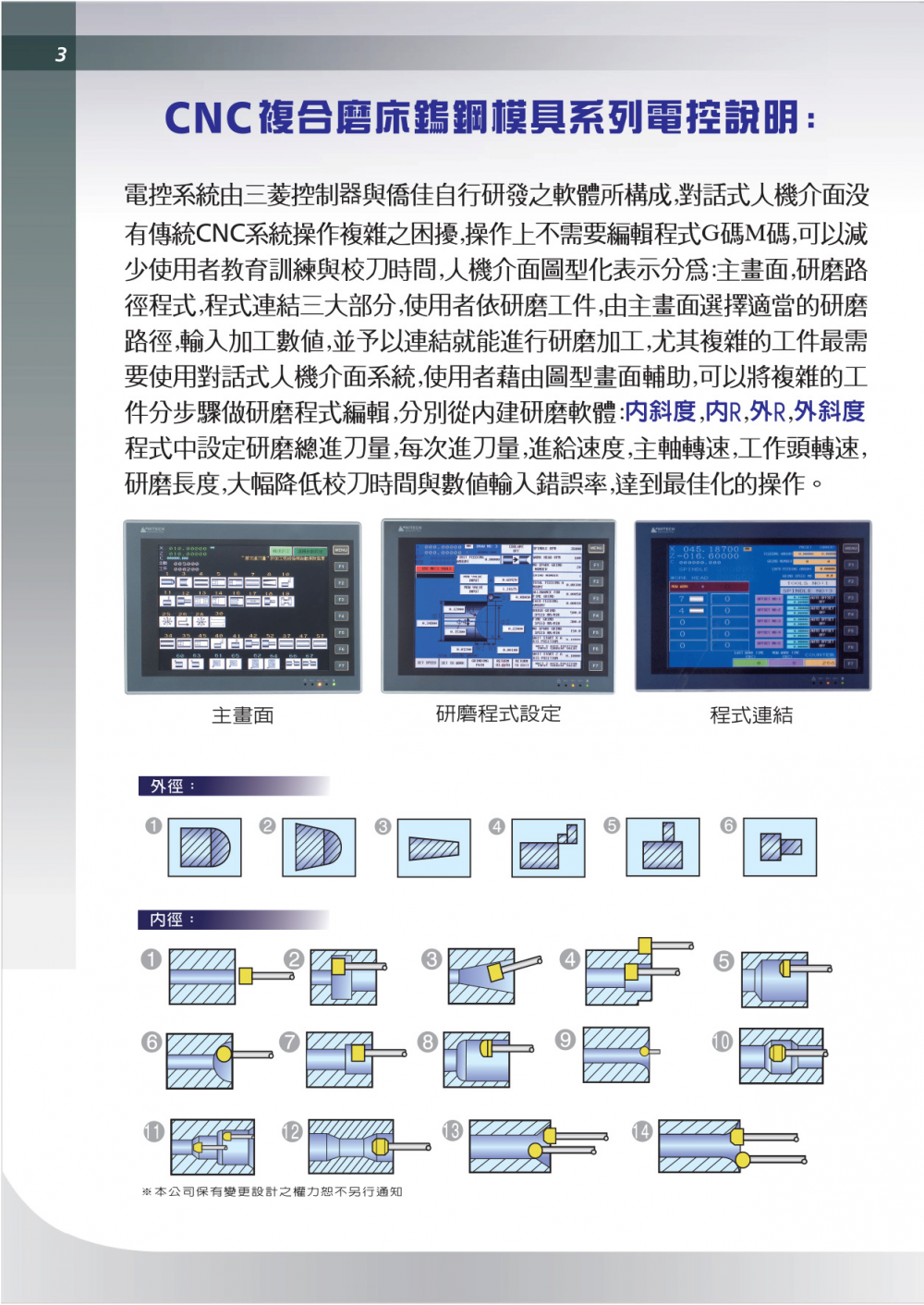

The most important feature of Jagura CNC Internal Cylindrical Grinders is that the grinding unit can be designed according to the customer's workpiece.Custom design capabilities are what we are most proud of.Jaguar provides customers with total solutions for internal, external and face grinding applications.Jagura can not only design the mechanism structure according to the workpiece clamping swing and workpiece length, but also set the spindle working position layout according to the customer's requirements.In addition, in terms of workpiece clamping, Jaguar provides a variety of clamping methods such as hydraulic soft chuck clamping, collet clamping, three-jaw chuck clamping and magnetic chuck clamping.In terms of control system, Jaguar has developed two control systems: 1. EASY CNC, 2. CNC for different grinding applications.Easy CNC: EASY CNC control system is specially developed for internal grinding, external grinding, face grinding and multi-step grinding.Both the X and Z axes are driven by ball screws and servo motors.The positioning accuracy can reach ±0.001mm.The control system is a user-friendly dialog operation interface.The operator only needs to select the desired grinding path, set the operating parameters and key in the desired grinding size, and the machine will automatically start the grinding process.Operators can easily operate EASY CNC series to edit G code and M code without manual operation.Numerical Control: The CNC control system is specially developed for profiling grinding of inner diameter/outer diameter taper, inner diameter/outer arc, etc.Both the X and Z axes are driven by ball screws and servo motors.The control system is a user-friendly dialog operation interface. The operator only needs to select the built-in grinding program, set the operating parameters and input the desired grinding size, and the machine will automatically perform the grinding process.Operators can easily operate the CNC series without editing G codes and M codes.In addition, it can be used with various measuring instruments to improve workpiece quality and production efficiency.Online series simple CNC NC JAG-ICG2512 SL11 SL11 JAG-ICG2512 SL20 SL20 JAG-ICG2012 SL11 SL11 JAG-ICG2012 SL20 SL20 JAG-ICG1512 SL11 SL11 JAG-ICG1512 SL20 SL20 Customized machines are welcome to accept spindle arrangement (3 axes of ICG 1512) Example of an internal grinding machine: ICG 3240 SL21 |

| |

|

| |

Product Image

Click Here Edit Paragraph Content

JAGURA carbide, metal mold JAG-ICG-S200-SL200-SL210, AG-ICG-SL410

|

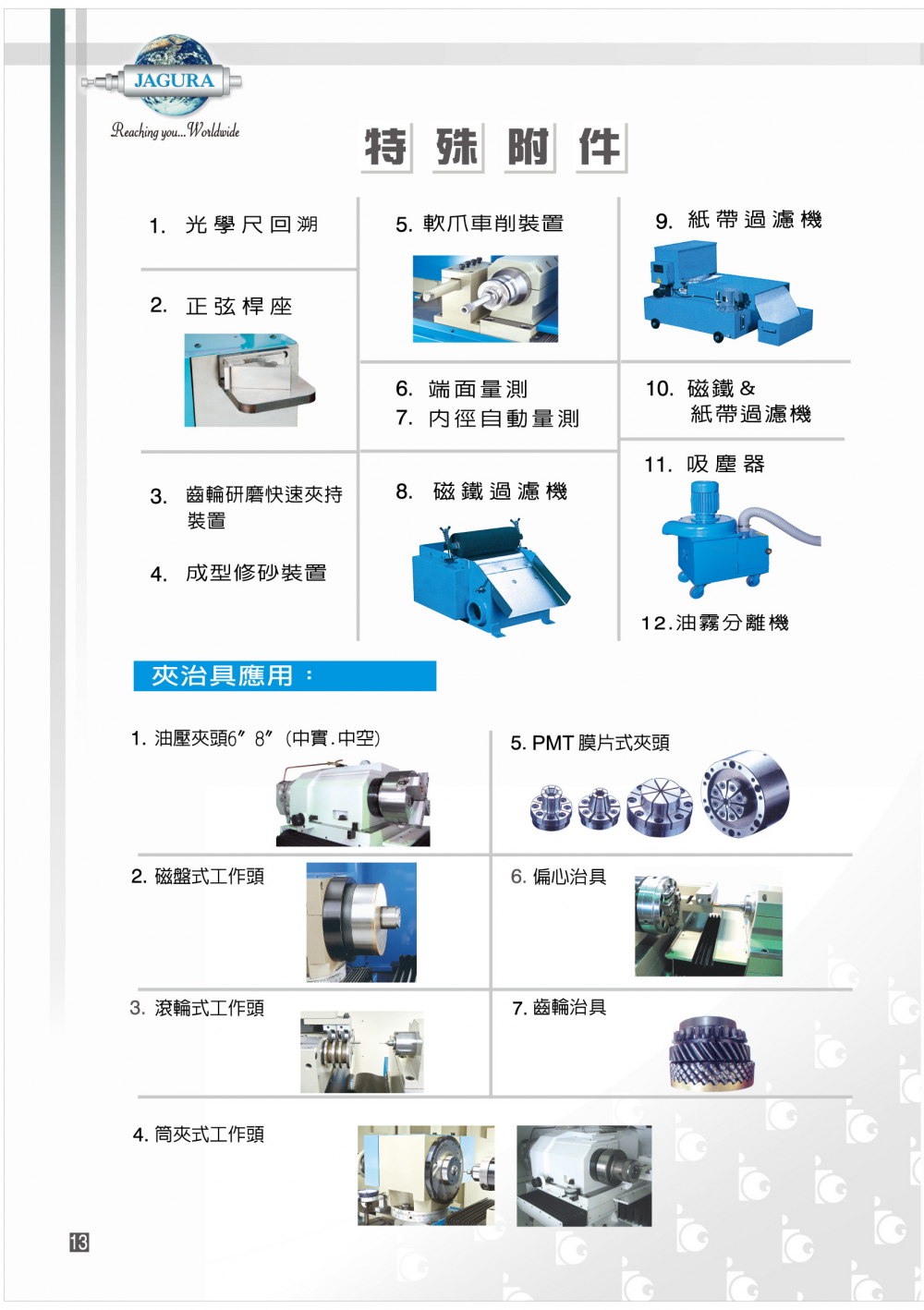

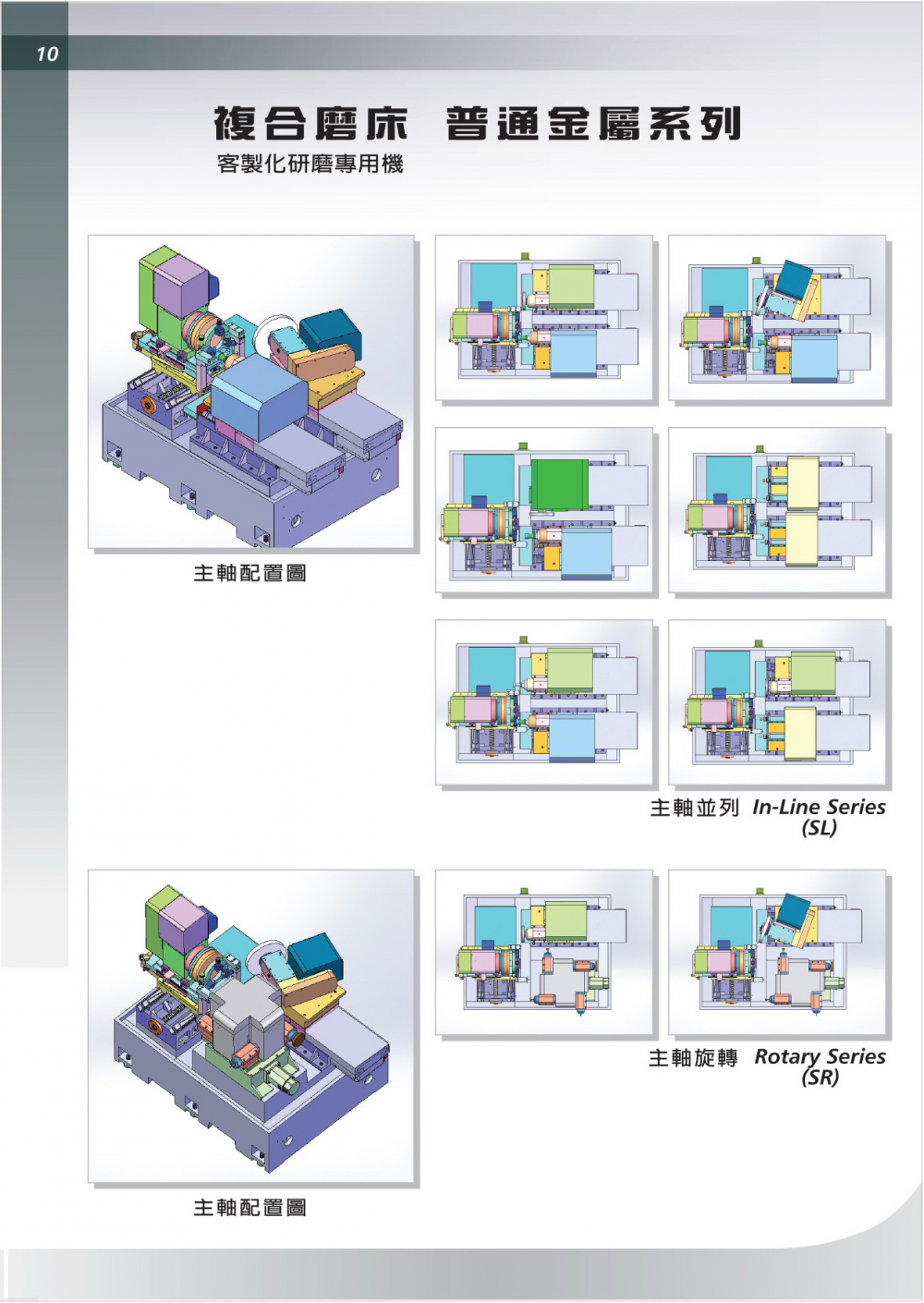

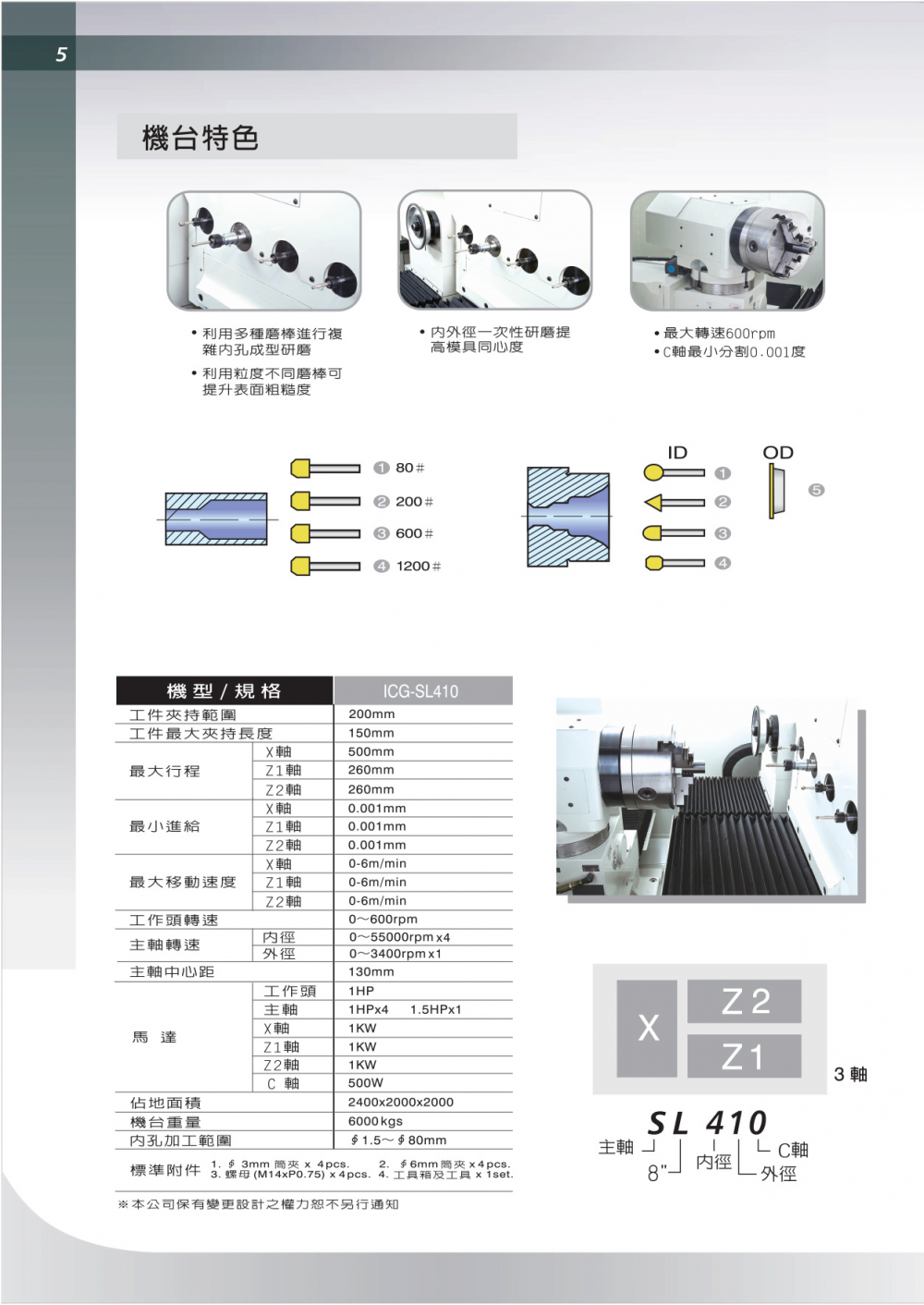

In the application of contour grinding of carbide mold inner holes, Jaguar offers a range of CNC internal cylindrical grinders, including models JAG-ICG-S200/ ICG-SL210/ ICG-SL410, for complex internal contour grinding, such as External and internal, especially the Z1 axis of JAG-ICG-SL410 carbide mold master is equipped with 4 internal grinding spindles, which can be installed on different spindles for complex internal thread grinding. , or you can install grinding rods of the same type with different particle sizes on different spindles to ensure the precision of the mold and make the surface roughness close to the mirror surface.The Z2 axis of the JAG-ICG-SL410 is equipped with a cylindrical grinding spindle for face grinding.Internal grinding and end face grinding can be completed in one charge, ensuring high concentricity of the mold.In terms of control system, it is equipped with our own user-friendly dialogue man-machine interface.The operator only needs to select the required built-in grinding program, set the operating parameters, input the required grinding size, and the machine tool will carry out the grinding process.The operator does not need to edit the G code and M code, the operation is very simple.This model is very practical and suitable for grinding screw dies, can dies, wire drawing dies, powder metallurgy dies and lost wax dies.Set the operating parameters, input the required grinding size, and then the machine will grind.Operators do not need to edit G-codes and M-codes.The operation is very simple.This model is very useful for grinding thread dies, can dies, wire drawing dies, powder metallurgy dies and lost wax dies.Set the operating parameters, input the required grinding size, and then the machine will grind.Operators do not need to edit G-codes and M-codes.The operation is very simple.This model is very useful for grinding thread dies, can dies, wire drawing dies, powder metallurgy dies and lost wax dies.Machine Close-up Carbide Die Series JAG-ICG-S200 JAG-ICG-SL200 JAG-ICG-SL210 JAG-ICG-SL410 Products Series_New |

| |

|

| |

Product Image

JAGURA Centerless Grinder JAG-12C-18C-1810C-SP

Product Image

JAGURA, Precision Micro Outer Diameter Grinder JAG-02, JAG-02SP

Product Image

Philips punch pin grinder (indentation)

Model JAG-PIN-ID-AAL | JAG-PIN-ID-SP Standard Accessories Ø3mm Collet x 1pc Ø6mm Collet x 1pc Nut (M14xP0.75) x1pc Tool Box and Accessories x 1set Application Philips Punch Pin (Indentation) Grinder

example image

Optional Accessories: Model JAG-PIN-ID-AAL JAG-PIN-ID-SP Clamping Diameter Ø1.5- Ø25mm Ø1.5- Ø25mm Max.Clamping unit length 120mm 120mm maximum.Travel from front to back 40mm 40mm Left to right 150mm 85mm Cross feeding graduation 0.0025mm 0.005mm Table speed 0-4m/min -------- Drum speed 0-380 rpm 0-380 rpm Rotation angle ±45° ± 45° Feeding mode from front to back automatic manual left to right automatic manual spindle speed 0-55000 rpm 0-55000 rpm main motor drum 25W 25W spindle 1 horsepower 1 horsepower front to back 12W ---- left to right 25W ---- Dimensions (LXWXH) 1000 x 800 x 1480 mm 900 x 700 x 1400 mm Weight 550 kg 200 kg

Polygon Punch Grinder Model JAG-06-SP Features It is designed to grind polygonal punches.And can also grind out horizontal lines.collet type

Optional accessories Photometer cooling system Optional accessories: Model JAG-06SP Clamping diameter Ø1-Ø20mm Maximum stroke from front to back 150mm Left to right 100mm Up or down 80mm Roller speed Manual rotation angle 0~360° Spindle speed 0-12000 Turn main motor 3/4HP, 3Ø Dimensions (LXWXH) 1200x1200x1600mm Weight 750kg Working range Ø0.8mm Example image

|

|

|

|

|

|

|